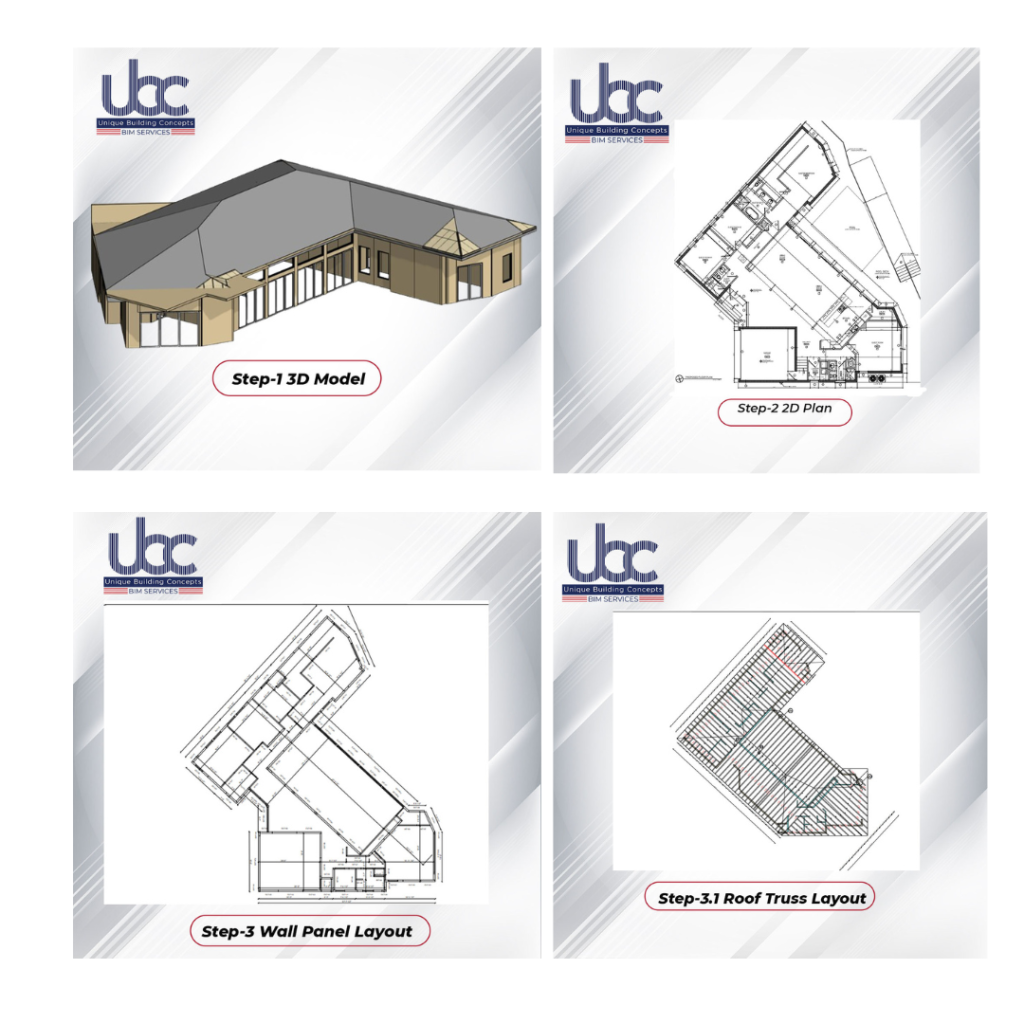

Project Overview

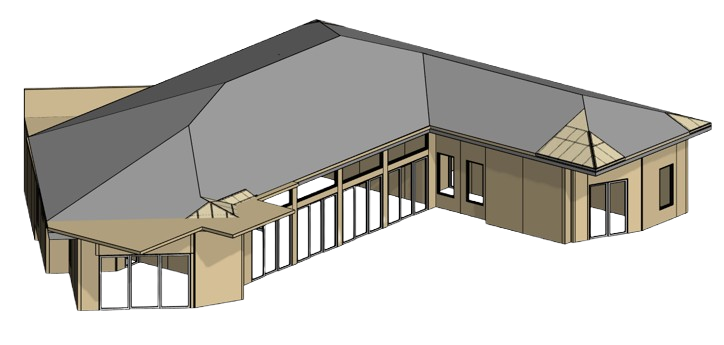

Every project is an opportunity to push the boundaries of structural efficiency and design precision. One of our recent hybrid Residential building project—of area 3,629 sq. ft. structure with a multi-slope roof is with the challenges and innovations required to meet complex load demands while simplifying execution.

Scope Of Work

This hybrid building required a structural system capable of handling heavy loads transferring across multiple roof planes. The multi-slope roof design made it particularly difficult to align the trusses efficiently due to inconsistent slopes and intersecting geometries.

Initially, the structural part included both in-plane and out-of-plane trusses to accommodate varying load paths. However, the mix introduced unnecessary complexity and coordination challenges. Building Information Modelling services from LOD 100 to LOD 500 in Florida, USA for both Cold Formed Steel and timber framed structures.

Scope Of Work Includes:

- Modeling

- Detailing

- Engineering

- CNC Production Files

- Roof Truss Package

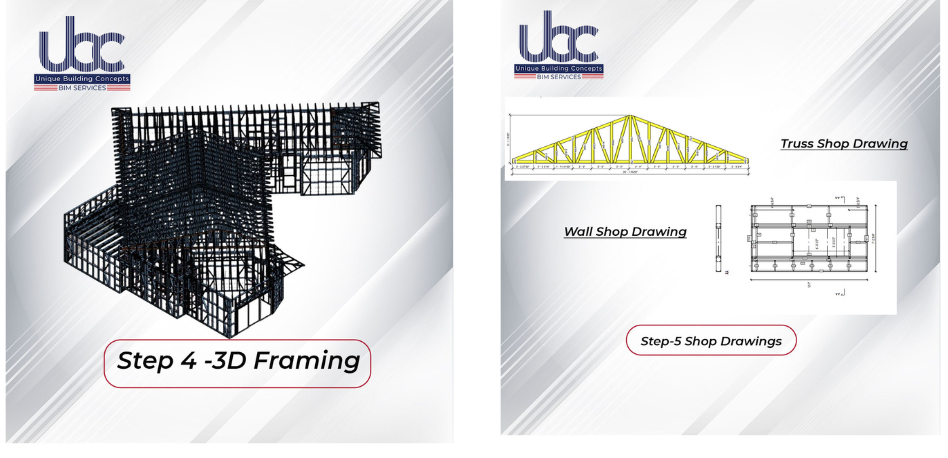

Truss Optimization Through Custom Engineering

By Using of Revit MWF Struct software, our engineering team carefully analysed the structure to understand load transfers between the slopes. After multiple simulations and iterations, we identified that the entire roof system could be supported using only out-of-plane trusses, thereby eliminating the need for dual truss types.

This strategic decision:

- Simplified installation

- Reduced detailing and fabrication time

- Enhanced overall constructability

- Maintained structural integrity for all heavy load paths

Software Used:

Using Vertex BD software we designed complete modelling, detailing and production files. This Hybrid residential building accounted for the complex multi-slope geometry and enabled us to develop clear and error free construction documents.

Machine Used:

Final outputs included CNC-ready production files fully optimized for Arkitech machine, allowing seamless offsite fabrication., the finalized truss package was manufactured with high precision was fed directly into the Arkitech Machine ensuring high-speed, zero-error manufacturing. This integration dramatically reduced on-site assembly time while maintaining the structural integrity and safety standards required for residential Building.

- Heavy load handling across multi-slope geometry

- Successful reduction from dual to single truss type

- Full automation with Arkitech CNC

- Seamless coordination between Revit (engineering) and Vertex (modeling/detailing)

Why UBC?

This project stands as a testament to UBC’s commitment to optimizing design without compromising strength or constructability. Our integrated workflow— design modeling, engineering, detailing, and CNC fabrication—ensures that even the most complex hybrid structures can be delivered with precision, speed, and confidence. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in the Florida, USA.