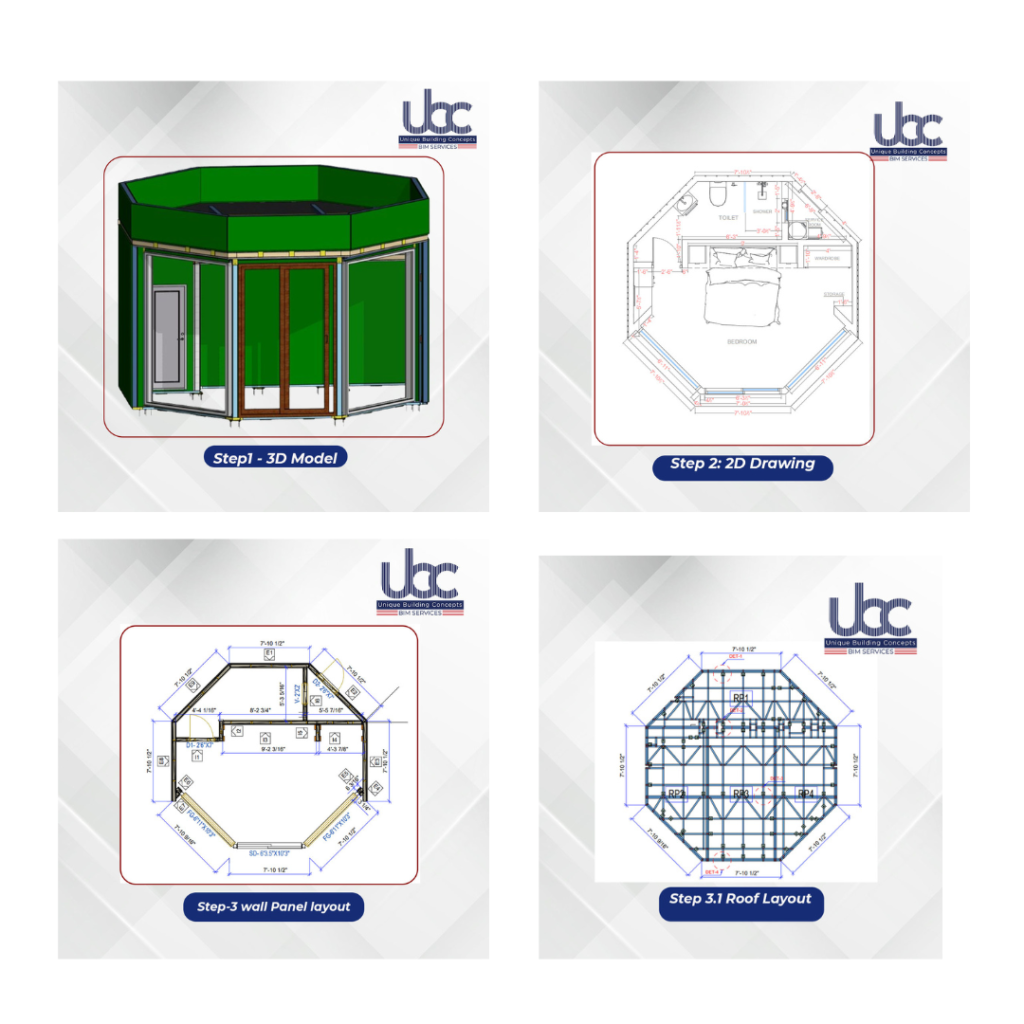

Project Overview

This project involved the engineering, modelling and detailing of a modular resort room concept using cold formed steel (CFS)comprising eight Octopod units each with an area of 299 sq. ft (8 units)in India. Designed as pick-and-drop structures, the units feature an octagonal shape and a mono-pitched roof. The unique geometry of the design presented challenges in framing. We continually push the boundaries of what’s possible in modular Cold formed steel (CFS)construction. This project demonstrates how strategic engineering and smart detailing can overcome geometric challenges to deliver high-performance, transportable spaces. Building Information Modelling services from LOD 100 to LOD 500 in India for both Cold Formed Steel and timber framed structures.

Scope of Work:

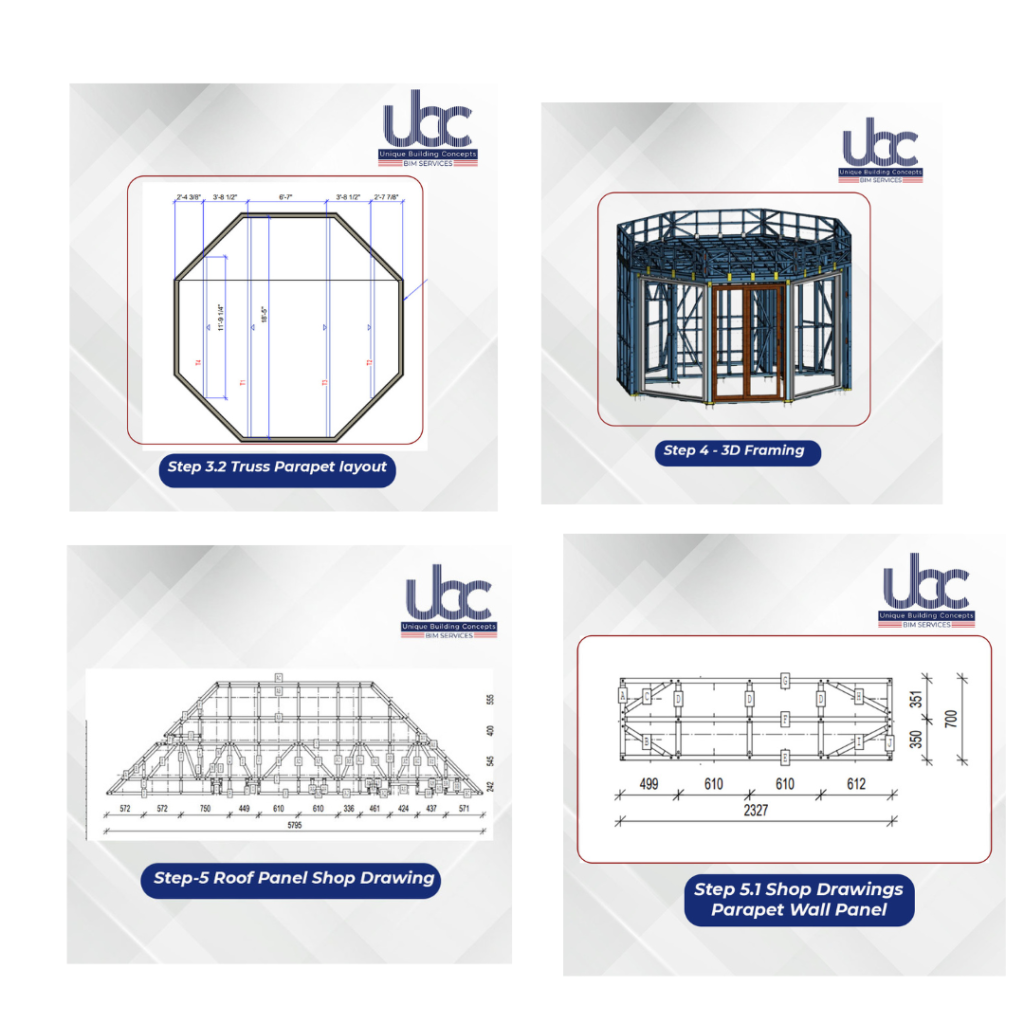

Our Team incorporated a standard framing connection strategy wherever possible to maintain compatibility with automated production workflows and simplify installation. The mono roof design was seamlessly integrated into the angular geometry, optimizing rain water drainage system and aesthetics.

Scope Of Work Includes:

-Engineering

-3D Modeling

-Detailing

-CNC Production files

Design Challenge:

Unlike conventional rectangular modules, this project featured an octagonal floor plan which introduced unique challenges

- Each corner required angled framing connections, deviating from standard 90-degree joins.

- Ensuring strength and stability in such non-linear layouts demanded careful engineering consideration, especially for transport and on-site installation.

Our Solution

To address the complexity of angled connections, our team incorporated Simpson Strong-Tie H6 plates strategically throughout the structure. These plates provided:

- Secure and rigid joints at octagonal corners

- Ease of installation without compromising structural integrity

- Compatibility with Howick machine outputs, ensuring smooth fabrication

Software

Using Vertex BD, Team designed Modelling, Detailing the entire structure, Engineering is done using Starp.

- Automated panel layout generation, even for non-orthogonal shapes

- Integration of structural detailing with exact placement for Simpson plates

Machine

Our Howick machine then transformed these intelligent designs into precise framing components, ensuring flawless fabrication and reducing material waste.

Modular, Transportable, and Built for Performance

Each Octopod module was designed to be:

- Easily transported and installed on various terrains

- Structurally sound with mono roof framing

- Aesthetically perfect for modern applications like remote offices, glamping units, or portable living spaces

Why UBC?

This project exemplifies how UBCBIM Services team combines technical expertise, advanced software tools, and practical connection solutions to deliver robust, transportable, and ready-to-install modular structures—even with non-standard geometries like octagons—ready to drop, connect, and serve.UBC UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in India.