Project Overview

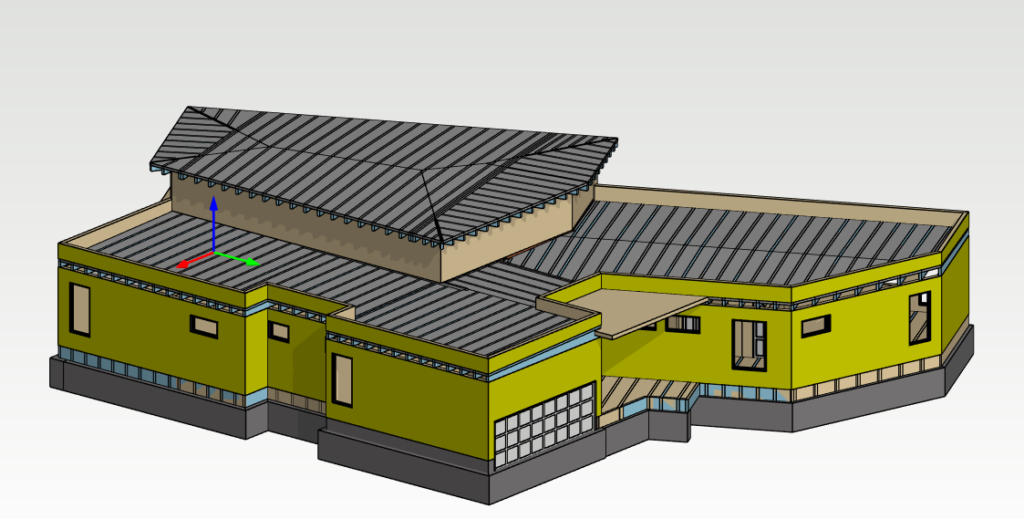

At UBC BIM, we continually strive to push the boundaries of modern residential construction using Cold Formed Steel technology. Our recent project of area 3,930 sq. ft. single-storey residential building in Florida, USA is a testament to innovation, precision, and seamless integration of advanced software and machinery. This project includes a full basement, first floor, and a striking roof system—carefully designed, engineered, and executed for maximum performance and aesthetic appeal. Building Information Modelling services from LOD 100 to LOD 500 in Florida, USA for both Cold Formed Steel and timber framed structures.

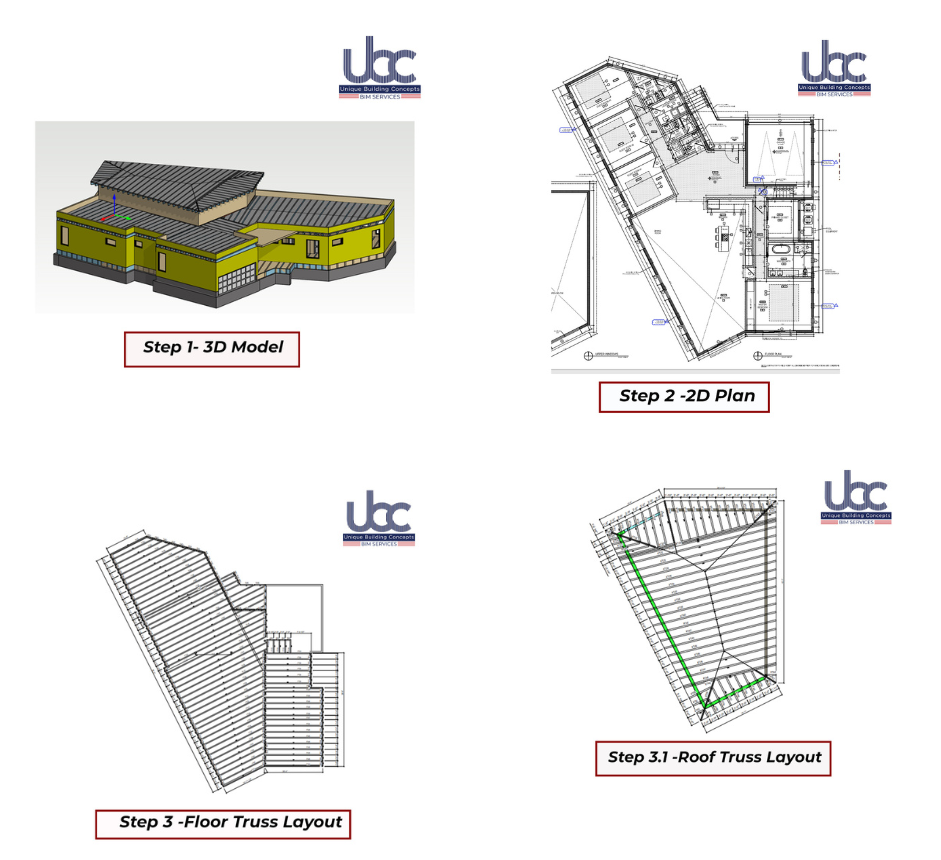

Scope of work:

A key highlight of the project was the LGSF-designed hip and mono roof systems, which not only added architectural elegance but also ensured robust structural performance. These roofs were carefully engineered to integrate seamlessly with the rest of the steel framing, enabling efficient load transfer and ease of on-site assembly.

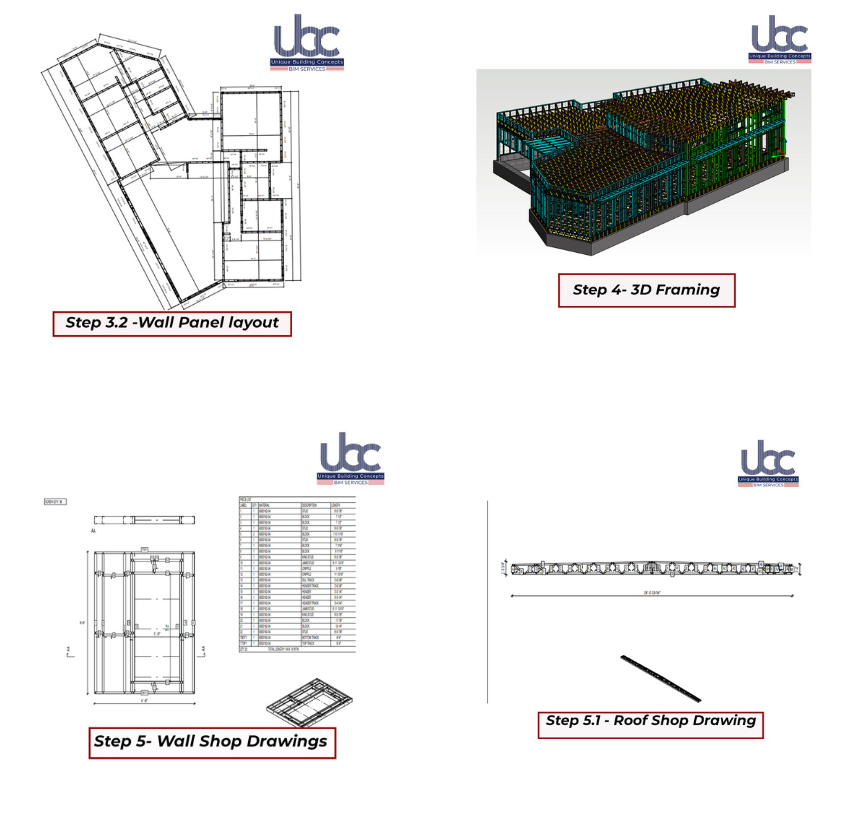

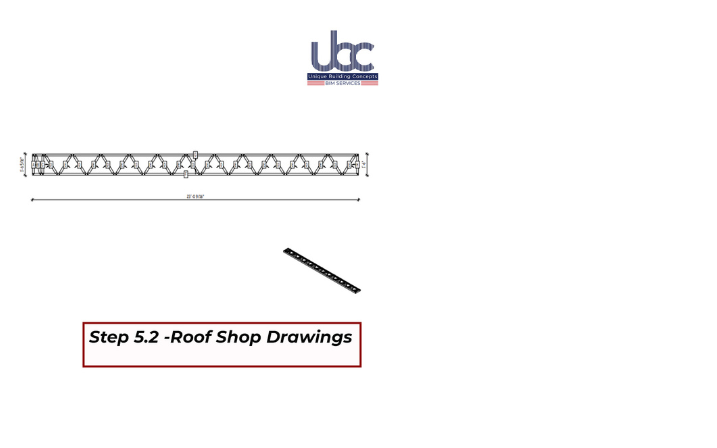

UBC BIM team delivered complete services including engineering, modeling, detailing, CNC production file generation, and shop drawings. The structural systems provided encompassed the floor framing system, wall framing system, and roof framing system featuring both mono and hip roofs.

As per the client’s requirement, the total build height was approximately 20 feet and designed with a single-story wall system. Due to the inclusion of large openings and the preference to avoid the use of red iron columns and beams, heavier LGSF profiles were incorporated. To meet these structural needs, a 10-inch wall profile was utilized, ensuring strength and stability while maintaining a pure LGSF solution throughout the building, including floor, wall, and roof framing systems.

Software Used

The project commenced with the client sharing architectural and HVAC plans. Our experienced team promptly translated these into 3Dmodels. Using Vertex BD, we design modeling, detailing, CNC production files and the creation of shop drawings, ensuring that every framing component aligned perfectly with architectural layouts.

Machine Used

Final outputs included CNC-ready production files fully optimized for Arkitech machine, allowing seamless offsite fabrication., the finalized truss package was manufactured with high precision was fed directly into the Arkitech Machine ensuring high-speed, zero-error manufacturing. This integration dramatically reduced on-site assembly time while maintaining the structural integrity and safety standards required for residential Building.

Structural Integrity with Simpson Strong-Tie Connectors

To ensure the compliance with structural standards, we incorporated Simpson Strong-Tie 3/4″ SIMPSONS ANCHOR BOLT 4 1/8″ LENGTH Connectors, H6-Hurricane connectors at critical junctions. These high-performance connectors added an extra layer of strength to the assembly and supported seamless on-site installation.

Conclusion

This residential building project in Florida, USA stands as a benchmark in modern Cold Formed Steel construction, demonstrating UBC’s capability to deliver precision-engineered, aesthetically appealing, and structurally robust buildings. By integrating advanced software like Vertex BD with Arkitech machine, and reinforcing structural integrity through Simpson Strong-Tie connectors, we ensured a fully coordinated, high-performance building solution. This project exemplifies our commitment to delivering complete, code-compliant, and installation-ready systems—setting new standards for innovation and efficiency in the residential construction in Cold formed steel industry. . UBC offers permit sets, pre-bid packages with 3D BIM model along with , modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in the Florida, USA.