Project Overview

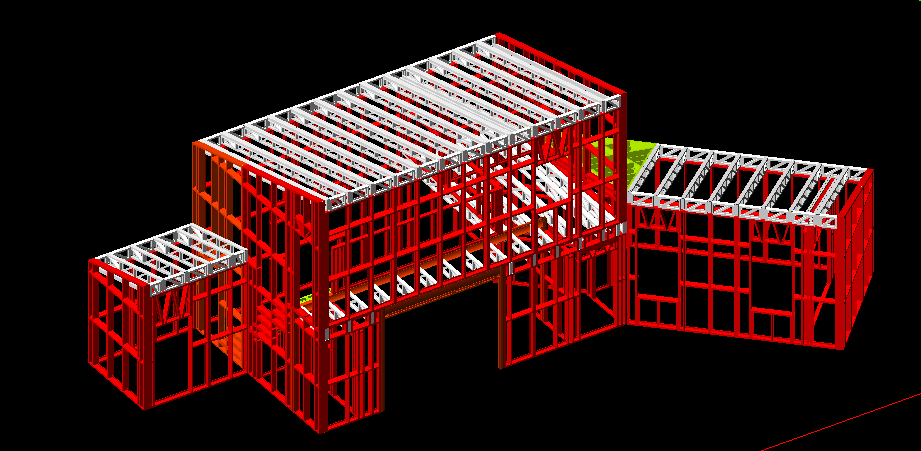

This project involved a two-storey residential building with a mono roof, covering a total area of 1,194 sq. ft. The structure was Modelled and detailed entirely using Light Gauge Steel Framing (LGSF) /cold formed steel in Georgia, USA to meet the local codes and site-specific requirements. A key highlight of the project is the inclusion of a pure LGSF staircase, engineered and fabricated completely from light gauge steel/cold formed steel without relying on conventional concrete or timber. The staircase was designed for strength, durability, and ease of installation, ensuring it integrates seamlessly with the overall framing system while maintaining consistency in material performance. This innovative approach highlights the versatility of LGSF in delivering not just the building shell but also critical structural elements like staircases, offering a modern, efficient, and sustainable solution. Building information modelling services from LOD 100 to LOD 500 in Georgia, USA for both light gauge steel and timber framed structures.

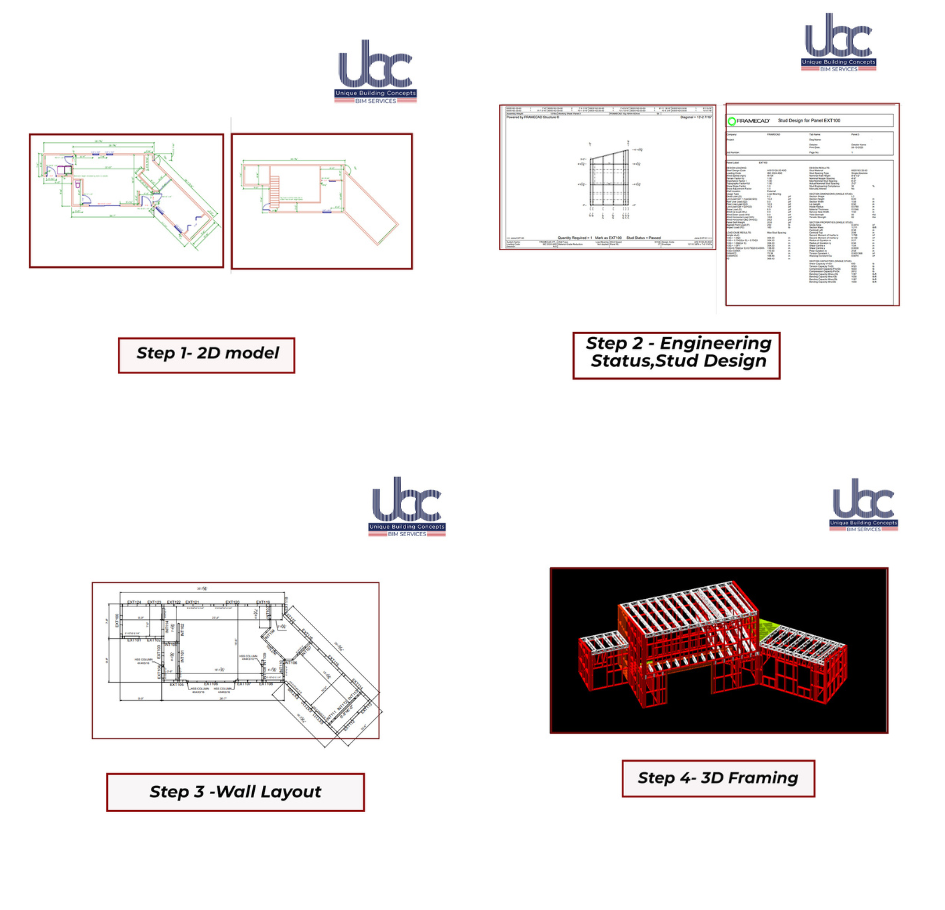

Scope of Work

Our team provided complete design-to-production support, which included:

- Engineering

- 3D Modeling

- Detailing

- Permit Sets

- CNC Files

Challenges and Solutions

Every project brings unique challenges, and this one required two special solutions:

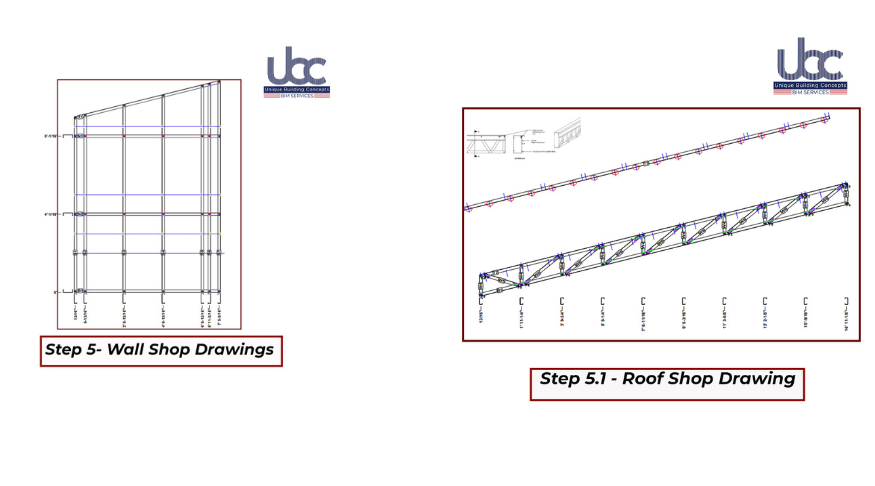

1.Long Truss Top Chords

- The roof design included extended-length truss top chords.

- Long members are prone to deflection if not properly reinforced.

- To overcome this, we used double reinforcement on the top chords, ensuring the trusses carried the loads safely and performed as required.

2.Uneven Floor Layout

- The floor plan had irregular areas where standard floor joist detailing was not possible.

- Instead of conventional joists, we used roof panels as floor joists.

- This approach provided a stronger connection system and ensured structural stability without compromising the design.

Software

The project was fully designed and detailed using FrameCAD structures. This platform enabled us to create accurate structural models, run engineering checks, and prepare detailed shop drawings. By using FrameCAD structures, we were also able to generate precise CNC files that were free from errors, ensuring a smooth transition from design to production.

Machine

For fabrication, the building components were produced on the FrameCAD machine. This advanced system ensured millimeter-level accuracy in cutting and punching, which reduced fabrication time and minimized material wastage. The result was a set of framing components that were ready for quick on-site installation, improving both efficiency and quality.

Conclusion

This residential project in Georgia highlights how innovative engineering and advanced technology can solve real-world construction challenges. By reinforcing truss chords and adapting roof panels as floor joists, we delivered a safe, strong, and efficient structural system. With the power of FrameCAD structures and machine, we provided a complete 3D modeling-to-fabrication package, ensuring faster installation and reduced on-site issues. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in the Georgia, USA.