Project Overview:

Our recent project is a 1-storey residential building using cold formed steel in the Washington DC , USA with a total built-up area of 3,466.9 sq. ft. The structure features a gable roof, ensuring both aesthetic appeal and durability. This project demonstrates our ability to combine engineering expertise with efficient production workflows for seamless on-site execution. Building information modelling services from LOD 100 to LOD 500 in Washington DC, USA for both light gauge steel and timber framed structures

Scope of Work :

Our team provided end-to-end engineering support for this project This ensured every stage—from modeling to production files—was completed with accuracy, speed, and constructability in mind.

Includes:

Key Features

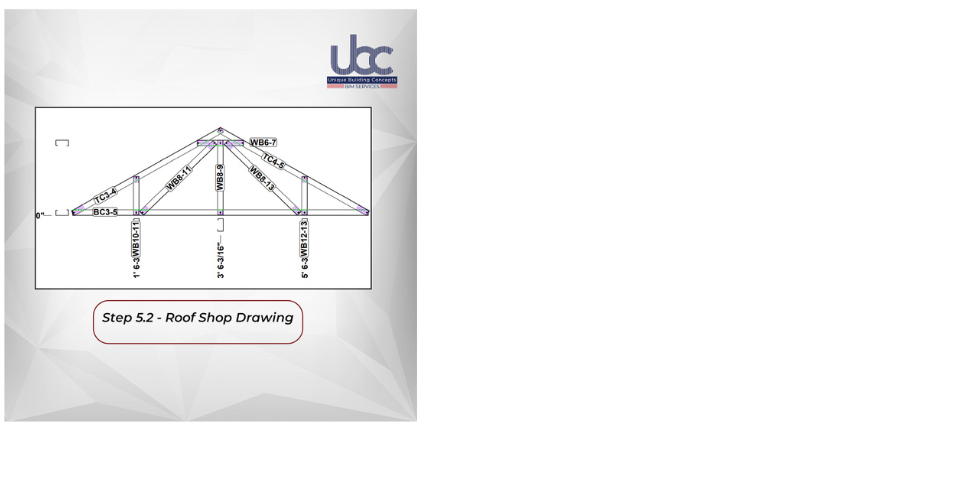

- Integration of valley trusses to enhance roof design and load distribution.

- Custom-designed open web header for the garage, improving structural efficiency while optimizing material usage.

- Precision detailing to align with on-site requirements and local building standards.

Software Used:

For this project, our team leveraged the combined power of Revit and MWF Advanced Metal:

- Revit: A robust BIM (Building Information Modeling) platform that enabled us to design, coordinate, and visualize the entire structure with high accuracy. With Revit, we developed a complete digital twin of the building, ensuring every element was modelled to meet both engineering and construction requirements.

- MWF Advanced Metal: Integrated within Revit, this software provided advanced framing and detailing tools specifically for light gauge steel. It allowed us to generate shop drawings, cut lists, and CNC-ready data directly from the model. This streamlined workflow reduced manual errors, enhanced detailing efficiency, and ensured seamless coordination between engineering and fabrication.

Machine Used:

The project’s production phase was executed using the FrameCAD Machine, a globally recognized leader in light gauge steel manufacturing technology:

- FrameCAD machines are designed for precision, speed, and reliability in cold-formed steel production.

- By processing CNC files directly from MWF Advanced Metal, the FrameCAD system automatically produced steel components with exact cuts, punches, and markings required for quick on-site assembly.

- This not only accelerated the fabrication process but also ensured consistency, minimized material waste, and reduced construction timelines.

Conclusion:

This project is a reflection of UBC’s commitment to engineering excellence, constructability, and efficient delivery. By leveraging cutting-edge BIM software like Revit and MWF Advanced Metal along with the advanced FrameCAD manufacturing system, we delivered a residential solution that not only meets design intent but also ensures ease of installation on-site. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in Washington DC, USA.