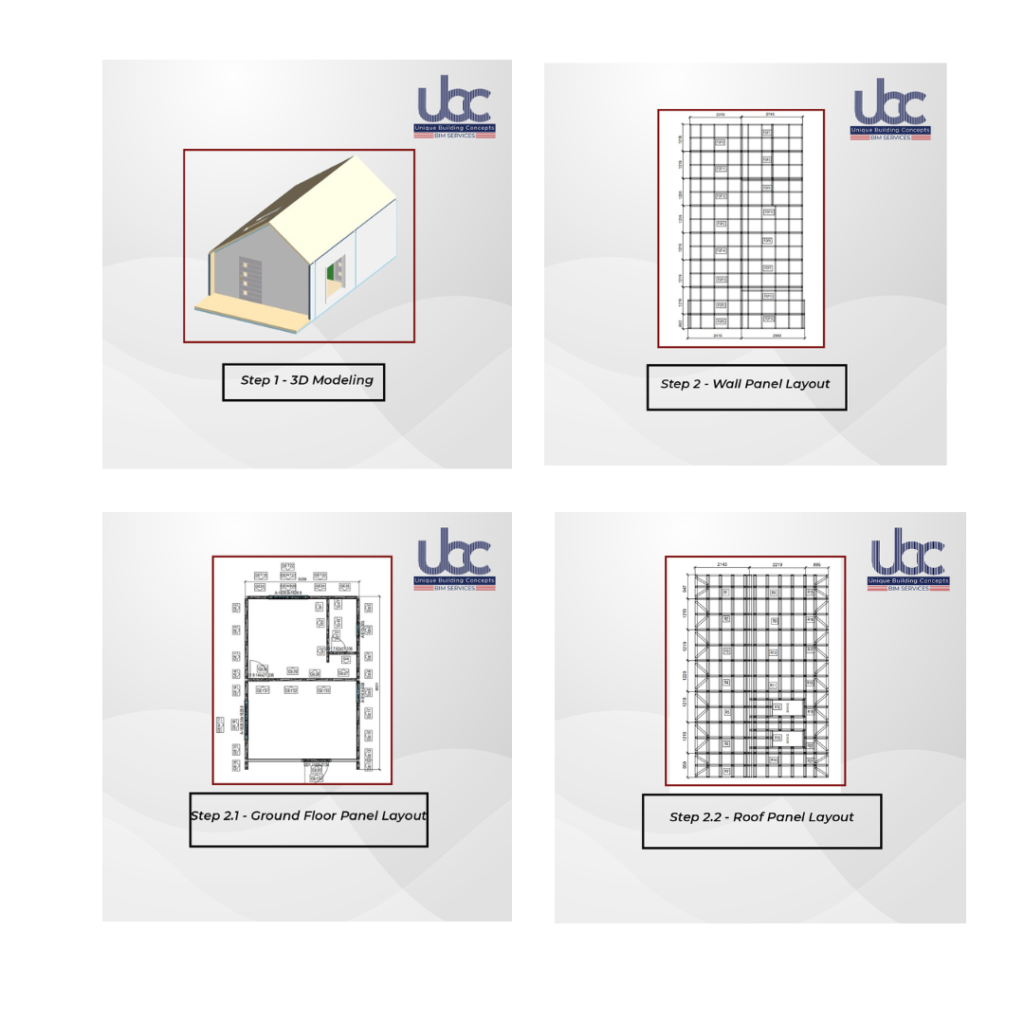

Project Overview

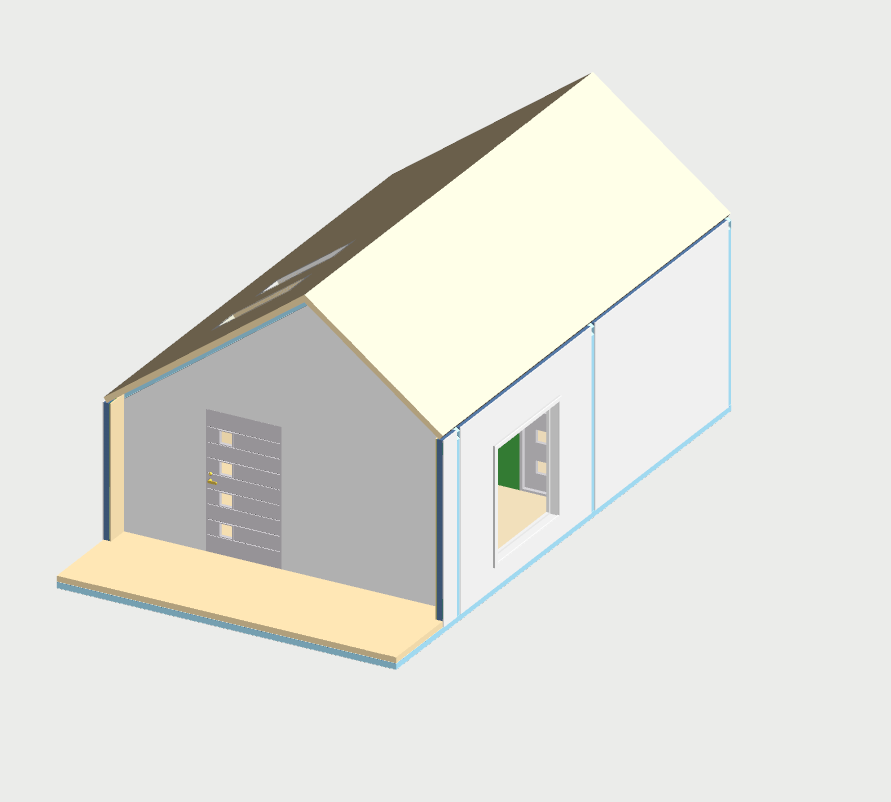

At UBC, we continue to push the boundaries of modular construction through intelligent engineering, advanced software, and automated manufacturing. Our latest 527.5 sq. ft., single-storey modular unit in India using cold formed steel demonstrates how thoughtful design and cutting-edge technology come together to deliver a structure that is efficient, precise, and installation-ready.

This compact yet highly functional modular unit features a gable roof and is engineered to optimize load transfer, stability, and long-term performance. Every element—from the floor to the roof—has been meticulously planned to align with manufacturing and on-site assembly requirements. Building information modelling services from LOD 100 to LOD 500 in India for both light gauge steel and timber framed structures.

Scope of Work

Our team delivered complete end-to-end services:

- Engineering

- 3D Modelling

- Detailed

- CNC Production Files

- Shop Drawings

Key Engineering Highlight

Floor Panel System: A standout feature of this unit is its floor structure, designed using advanced floor panel systems. This approach delivers:

- Uniformity across all modules

- Faster onsite installation

- Reduced labour requirements

- Improved alignment and load distribution

By integrating a standardized floor panel system, we ensure each unit fits seamlessly during assembly—an essential factor in modular construction where precision is critical.

Software Used:

This project was executed using a powerful combination of advanced software and high-precision manufacturing technology. STRAP was utilized for comprehensive structural analysis and safe load validation, ensuring the unit met all performance requirements. Vertex BD enabled accurate 3D modeling, clash-free detailing, and the generation of CNC-ready production data, creating a seamless digital workflow from design to fabrication.

Machine Used:

For manufacturing, the unit was produced using Howick’s machine, which transformed the design data into precise components with millimetre-level accuracy, reducing errors and significantly accelerating the overall production process

- Zero design-to-production errors

- Highly accurate components

- Faster assembly timelines

- A robust, durable modular unit ready for deployment

Conclusion

This 527.5 sq. ft. modular unit is a testament to UBC’s commitment to engineering excellence and manufacturing precision. By uniting advanced software, automated roll-forming, and efficient panelised systems, we have delivered a solution that is not only structurally sound but also optimized for rapid, hassle-free installation. As the demand for smarter, faster, and more reliable modular infrastructure grows, UBC continues to lead with innovation-driven processes that redefine the future of construction. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in India.