At UBC BIM, we believe Building Information Modeling is not just about creating 3D models—it’s about delivering constructible, precise, and predictable buildings.

This 12-day journey of our 2-storey residential building in Texas, USA showcases how our BIM-driven workflow transforms an idea into machine-ready Light Gauge Steel (LGSF) construction with efficiency, accuracy, and confidence. Building information modelling services from LOD 100 to LOD 500 in Texas, USA for both light gauge steel and timber framed structures.

Managing multi slope-roof truss configurations is typically one of the most complex aspects of residential and light commercial projects. Variations in roof slopes, intersecting ridges, valleys, step-down roofs, and load transfer paths often introduce significant coordination challenges during design and detailing.

In this project, the presence of multiple roof truss systems initially posed a high level of complexity due to:

- Differing roof geometries and pitches

- Intersections between gable, hip, and mono roof sections

- Accurate alignment of trusses with supporting walls and beams

- Load continuity and proper load distribution across roof planes

By leveraging the advanced capabilities of Vertex BD, this challenge was efficiently transformed into a streamlined and highly controlled workflow. Vertex BD’s parametric truss modeling, intelligent connection logic, and real-time clash detection enabled precise coordination between roof trusses, wall panels, and supporting structural elements.

Vertex BD software allowed:

- Seamless modeling of complex roof intersections

- Accurate definition of truss profiles, spacing, and bearing conditions

- Automatic generation of shop drawings and material take-offs

- Early identification and resolution of constructability issues

As a result, what is traditionally considered a high-risk and time-consuming task became a well-coordinated, error-minimized, and production-ready solution. The use of Vertex BD not only improved design accuracy but also ensured smoother fabrication, faster installation on site, and reduced rework—demonstrating how advanced BIM-driven detailing can simplify even the most complex multi-roof truss challenges.

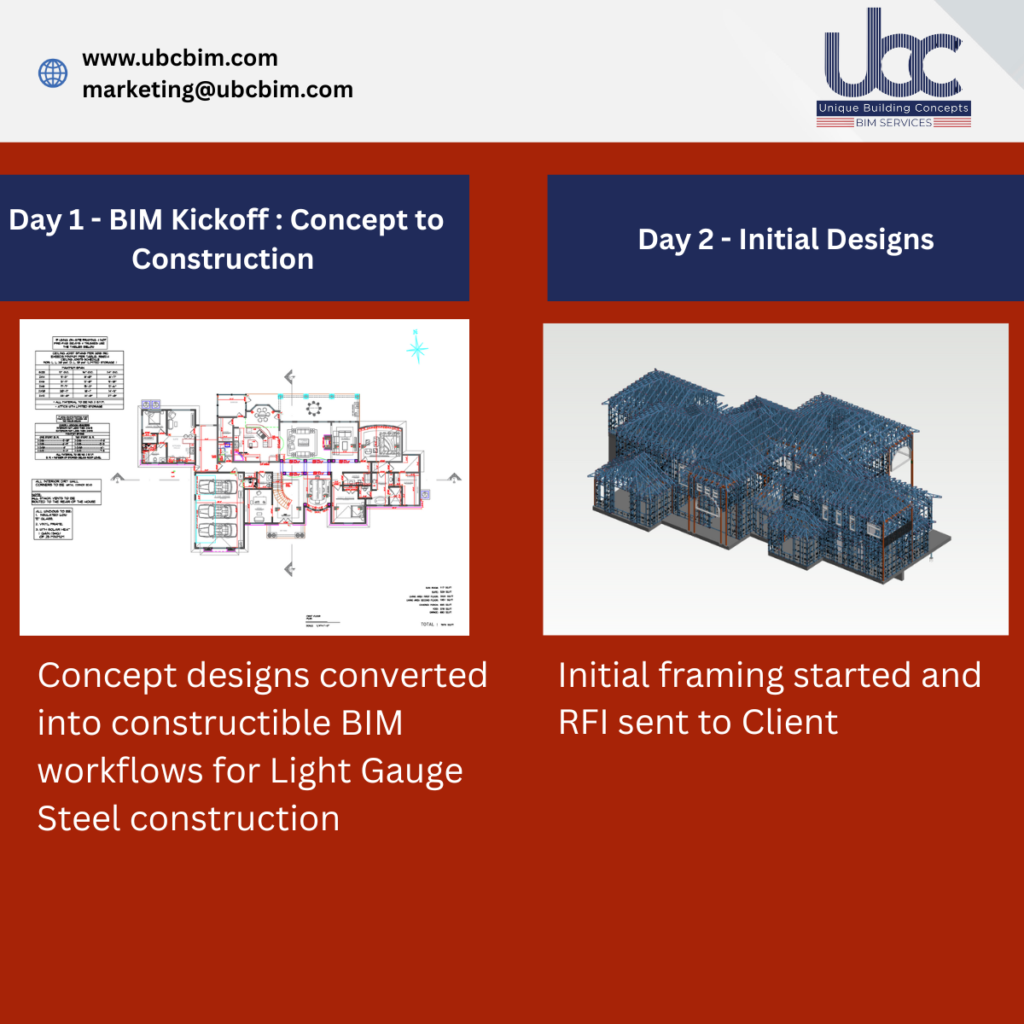

Day 1 – BIM Kick-off: Concept to Construction

Every successful project starts with a strong foundation.

On Day 1, our multidisciplinary BIM team initiates the kick-off by collaboratively reviewing architectural concepts, project scope, design intent, applicable codes, and constructability requirements.

Early coordination with Our architects, design engineers and detailer and fabrication team work together to analyze concept drawings and convert them into GA drawings (General Arrangements drawings) specifically optimized for Light Gauge Steel construction ensures fewer downstream changes and a smoother execution.

Day 2 – Initial Designs

With the concept aligned, our framing and BIM coordination team moves into initial layout and framing development.

Preliminary LGS framing begins, and our team proactively identifies critical RFIs and shares them with the client at an early stage.

This collaborative approach eliminates ambiguity, avoids assumptions, and ensures design clarity before detailed modeling begins.

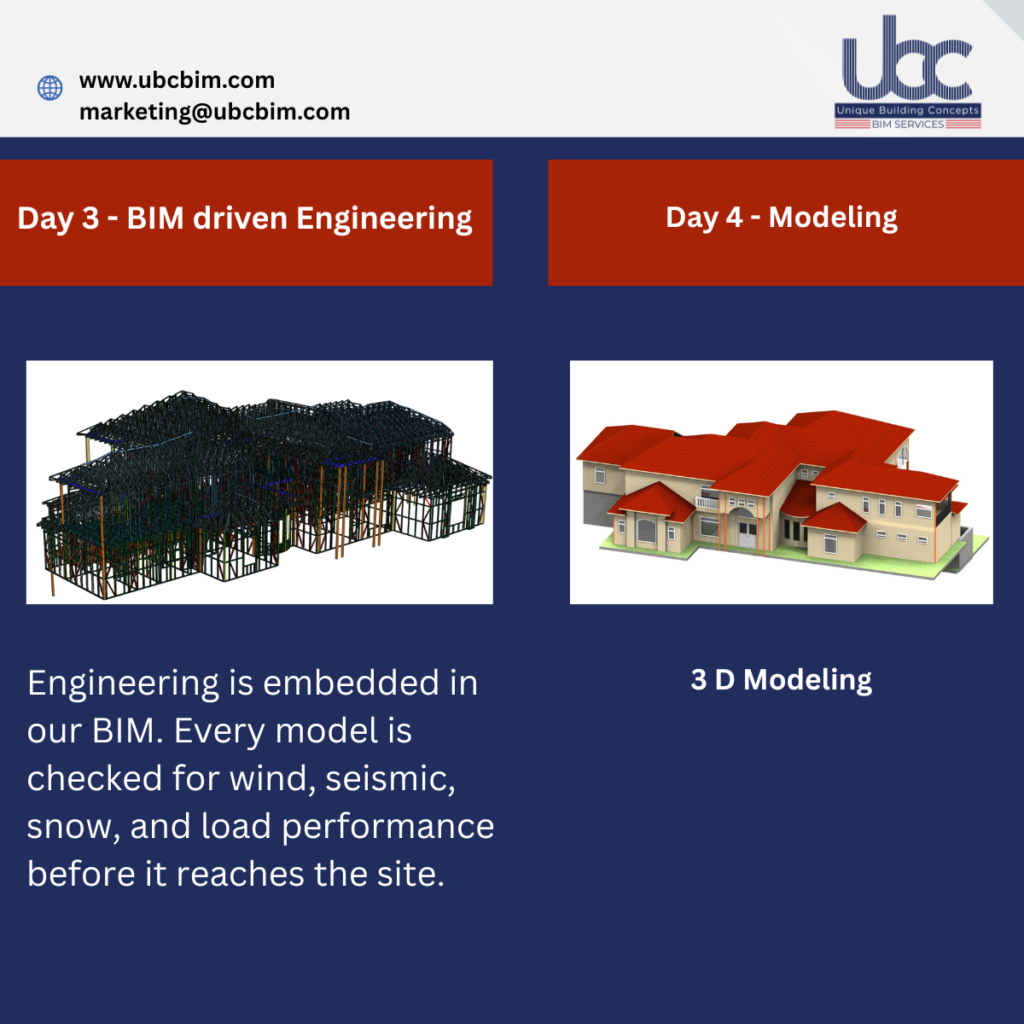

Day 3 – BIM Engineering

Engineering is embedded directly into our BIM models by our in-house engineering team.

Each structural element is analyzed for:

- Wind loads

- Seismic forces

- Snow loads

- Gravity and service loads

By integrating engineering early, our team ensures every model is not just visually accurate but structurally compliant and site-ready—long before it reaches the field.

Day 4 – 3D Modeling

Once engineering parameters are confirmed, our BIM modeling team develops detailed 3D models.

Walls, floors, roofs, and structural systems are 3D modelling with precision, enabling clear visualization for stakeholders and accurate coordination across all disciplines.

This stage reflects the seamless collaboration between our designers, engineers, and detailers—bridging design intent with real-world construction.

Day 5 – Hybrid Structures Done Right

Modern buildings often combine multiple structural systems.

On Day 5, our experienced coordination team carefully integrates Light Gauge Steel, red iron, and other structural elements within a single BIM environment.

Our team ensures alignment between all systems, preventing clashes, misfits, and costly on-site rework—especially critical in hybrid construction projects.

Day 6 – Precision Detailing with Constructability

This is where UBC BIM’s detailing expertise truly stands apart.

Our detailers model every stud, track, truss, and connection with fabrication-level precision, considering:

- Machine constraints

- Panel sizes

- Transportation limitations

- Installation sequencing

By working closely with fabrication requirements in mind, our team ensures components are machine-ready and easy to assemble on-site.

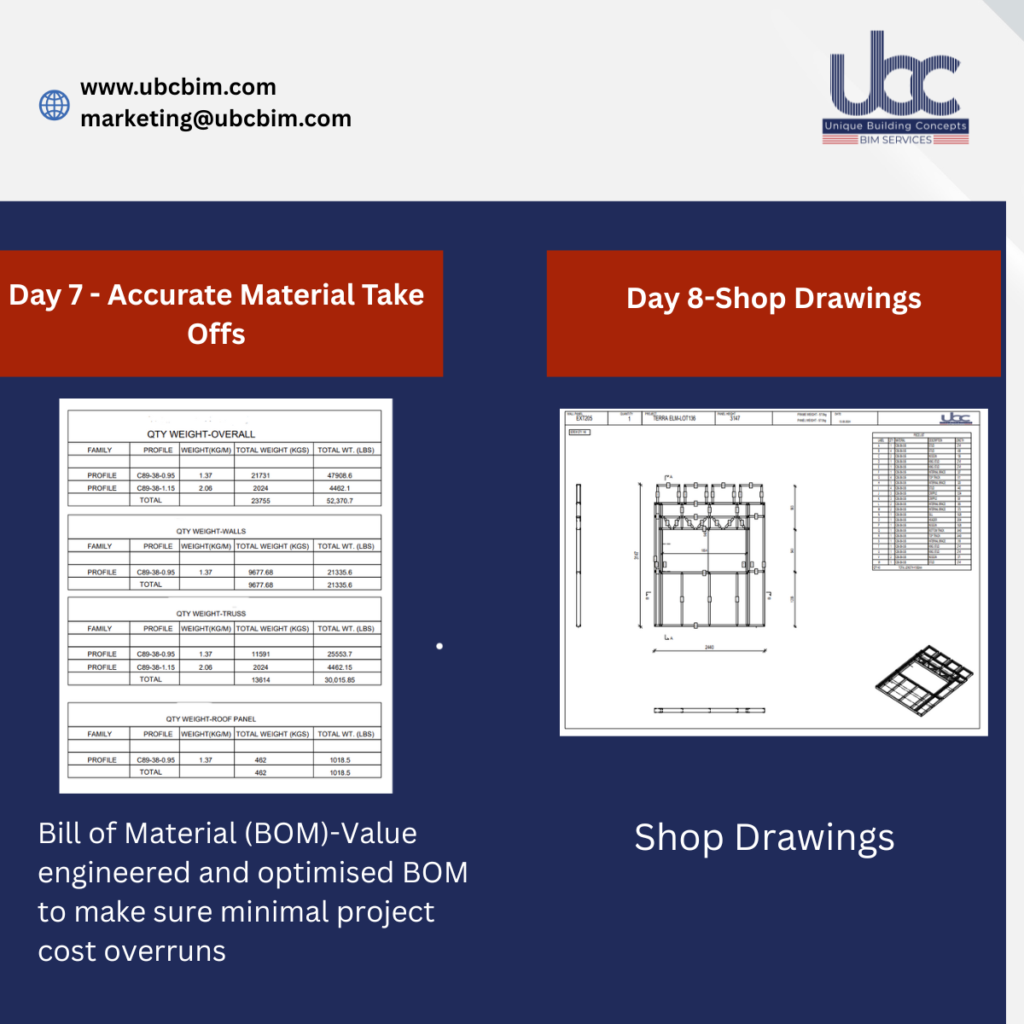

Day 7 – Accurate Material Take-Offs

With models finalized, our BIM and estimation team generates highly accurate Material Take-Offs (MTOs) and Bills of Materials (BOM).

Our value-engineered and optimized BOMs help:

- Reduce material waste

- Control project costs

- Avoid procurement surprises

This accuracy is the result of disciplined modeling and cross-checking by our experienced team.

Day 8 – Shop Drawings

Detailed shop drawings are produced by our shop drawing specialists for fabrication and installation teams.

These drawings clearly communicate dimensions, profiles, connections, and assembly sequences—ensuring smooth manufacturing and efficient site execution.

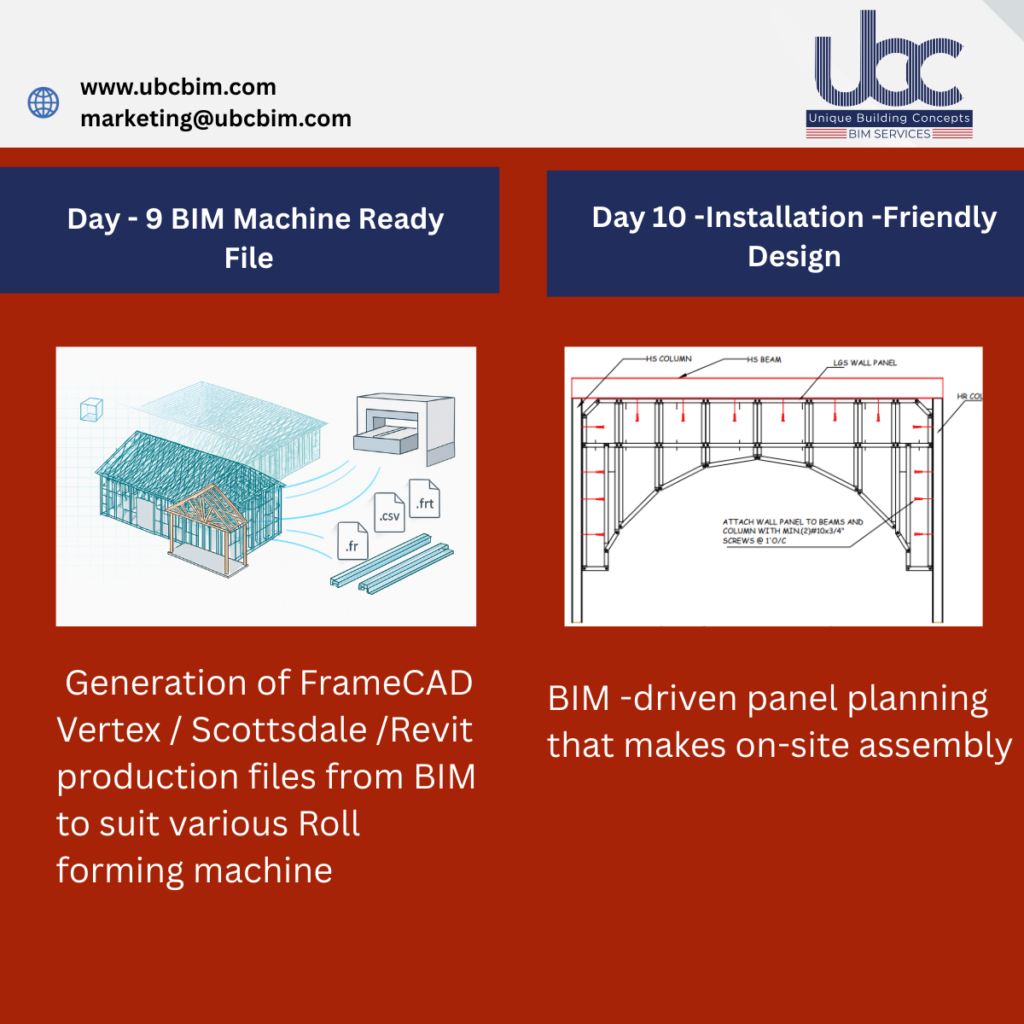

Day 9 – Panelization Strategy

At this stage, our BIM and logistics planning team optimizes the model for panelization.

Walls, floors, and roof panels are efficiently divided to balance:

- Fabrication efficiency

- Transportation feasibility

- On-site handling and installation speed

This thoughtful planning reduces labor time and improves overall site productivity.

Day 10 – Machine-Ready Output

Our BIM team converts the finalized model into machine-compatible files for roll-forming and CNC files. Final Output files include shop drawings, Layouts, output files for productions, panel drawing, connection details, typical sections and elevation etc. Because constructability is considered by our team from Day 1, the transition from model to machine is seamless—no rework, no guesswork.

Day 11 – Global BIM Support (24/5)

UBC BIM is powered by a globally distributed team delivering 24/5 support.

Our round-the-clock workflow ensures:

- Faster turnarounds

- Continuous progress across time zones

- Immediate issue resolution

This allows our clients to move forward without delays, regardless of location.

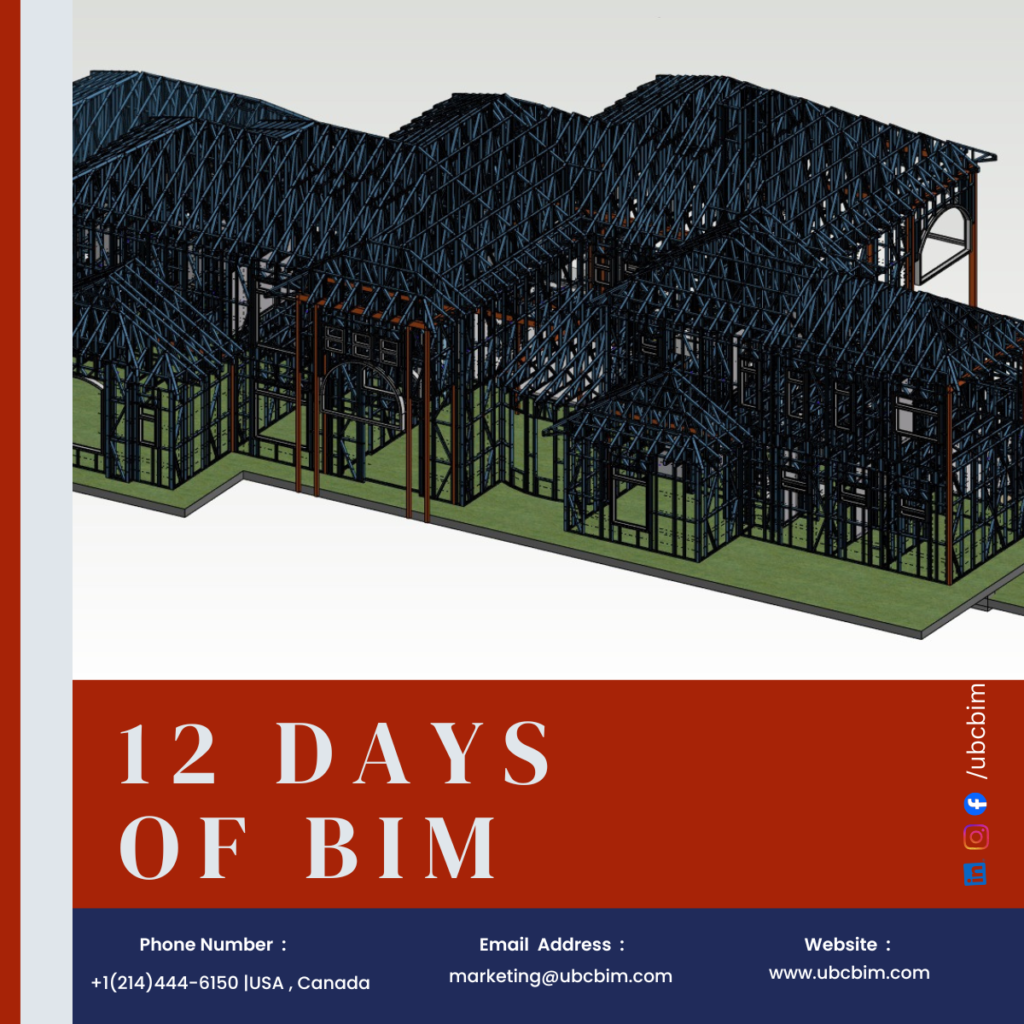

Day 12 – From BIM to Build Home

The final result reflects the combined effort of our entire UBC BIM team—a fully coordinated, engineered, and fabrication-ready BIM package that moves effortlessly from first model to final panel.

Our BIM process ensures:

- Predictability

- Precision

- Performance

What begins as a digital concept becomes a real, buildable, high-quality steel structure, delivered on time and on budget.

Why UBC BIM?

- Specialized in Light Gauge Steel & Hybrid Structures

- BIM-driven engineering and detailing

- Machine-ready fabrication outputs

- Fast turnaround with global support

- Focus on constructability, logistics, and installation

At UBC BIM, we don’t just model buildings—we build confidence before construction begins.

Conclusion:

From concept to construction, UBC BIM’s 12-day workflow demonstrates how BIM is useful when done right, becomes a powerful engine for predictability, precision, and performance. By embedding engineering, constructability, and fabrication intelligence into every stage, we help our clients reduce risk, control costs, and deliver high-quality Light Gauge Steel buildings with confidence. At UBC BIM, BIM isn’t just a process—it’s the foundation of smarter, faster, and better construction. This 12-day BIM journey reflects UBC BIM’s commitment to delivering more than models—we deliver clarity, coordination, and constructible solutions. Our integrated approach ensures that every decision made digitally translates seamlessly to the site, enabling our clients to build with certainty, efficiency, and peace of mind. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in Texas , USA.