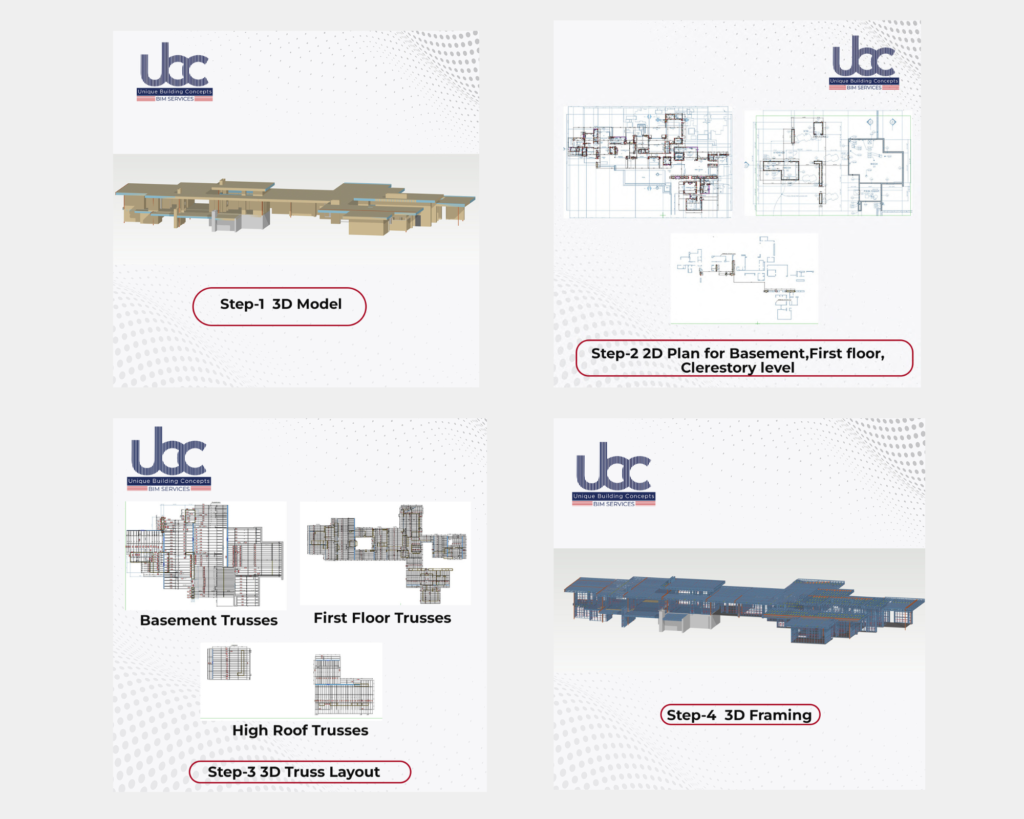

Overview

At UBC, we thrive on solving complex design and construction challenges, and our recent custom hybrid residential project in Arizona is a perfect example. Spanning a massive area of 18,315.17 sq. ft., this Ground + 1 floor building is a project presented unique engineering challenges due to its large size, large span trusses and hybrid structure. From modelling to production, every step was carefully planned to ensure structural stability, efficiency, and precision.

Hybrid Complexity, Simplified with Technology

This structure is a hybrid marvel blending Light Gauge steel framing, red iron components to achieve both architectural intent and structural stability. Given the large building footprint maintaining performance and constructability demanded a robust coordination strategy.

Software Used

Vertex BD software is used to complete the full modelling, detailing and CNC file generation for this building. Vertex BD allows us to handle complex structural elements and seamlessly coordinate between different building materials—cold-formed steel (CFS) and red iron steel (Red Iron)/structural Steel.

Machine Used

Once the detailing and production files are completed, all CFS components were manufactured using Howick Frama 3200 and Frama 5600 machines. This ensured that every panel, joist, and truss was produced with millimeter precision, ready for efficient on-site installation.

Hybrid Framing System

The main structure of the building is hybrid by combining cold-formed steel panels with red iron steel /structural steel beams, building information modelling services from LOD 100 to LOD 500 in Arizona for both light gauge steel and timber framed structures. This combination helps manage the structural loads efficiently, especially considering the large spans and overhangs in the design.

- Large Overhangs: These are supported using red iron steel /structural steel members to ensure durability and strength.

- Trusses and Floor Joists: Designed using cold-formed steel, these connect to the red iron steel/structural steel beams using joist hangers.

- Truss to Wall Connections: Secured with ½” bolts, ensuring firm and safe installation.

- Truss Chord Reinforcements: Provided as a typical detail to strengthen the top and bottom chords of the trusses.

- Truss Bridging: Installed to prevent lateral movement and improve overall stability.

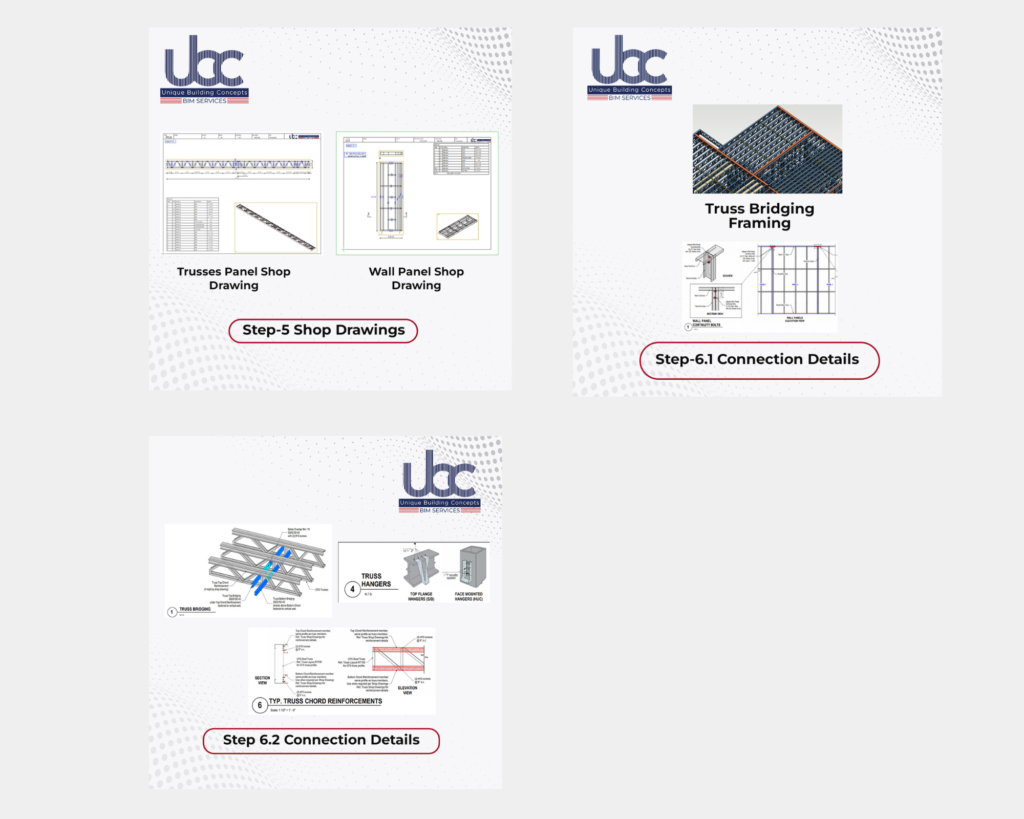

Panel Connections

The panel connections play a crucial role in the overall strength and ease of installation on-site. We designed the following:

- Panel-to-Panel Connections: Achieved using screws and panel bolts.

- CFS panel-to-panel connections were executed using a combination of self-drilling screws and panel bolts spaced to satisfy shear and pull-out resistance requirements.

- End studs in CFS wall panels were bolted using through bolts and structural washers, providing axial load continuity and lateral bracing at junction points.

- Joist-to-beam and truss-to-red iron interfaces included bearing plates and clip angles where necessary, engineered for slip resistance and ease of on-site installation.

Conclusion:

This Arizona residence wasn’t just about size—it was about making sure that every element came together as one integrated system. From large-span trusses to intricate wall panel interfaces, every detail was handled with foresight and precision. Our expertise in handling large hybrid structures by combining smart software tools like Vertex BD with advanced manufacturing technologies such as Howick machines. By carefully managing the connection details and using the right materials, we ensured that this 18,315 sq. ft. residential home building is strong, efficient and ready for long-term performance. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures, construction services in the Arizona, USA

If you’re planning a complex residential or commercial project and need a reliable partner for LGSF and hybrid structures, UBC is here to help—from design to production.