At UBC, we take pride in delivering fast, accurate, and constructible solutions regardless of project complexity. Our recent project two Storey Residential Building in Arkansas, USA, showcases our ability to tackle challenging site conditions while maintaining exceptional turnaround times.

Project Overview

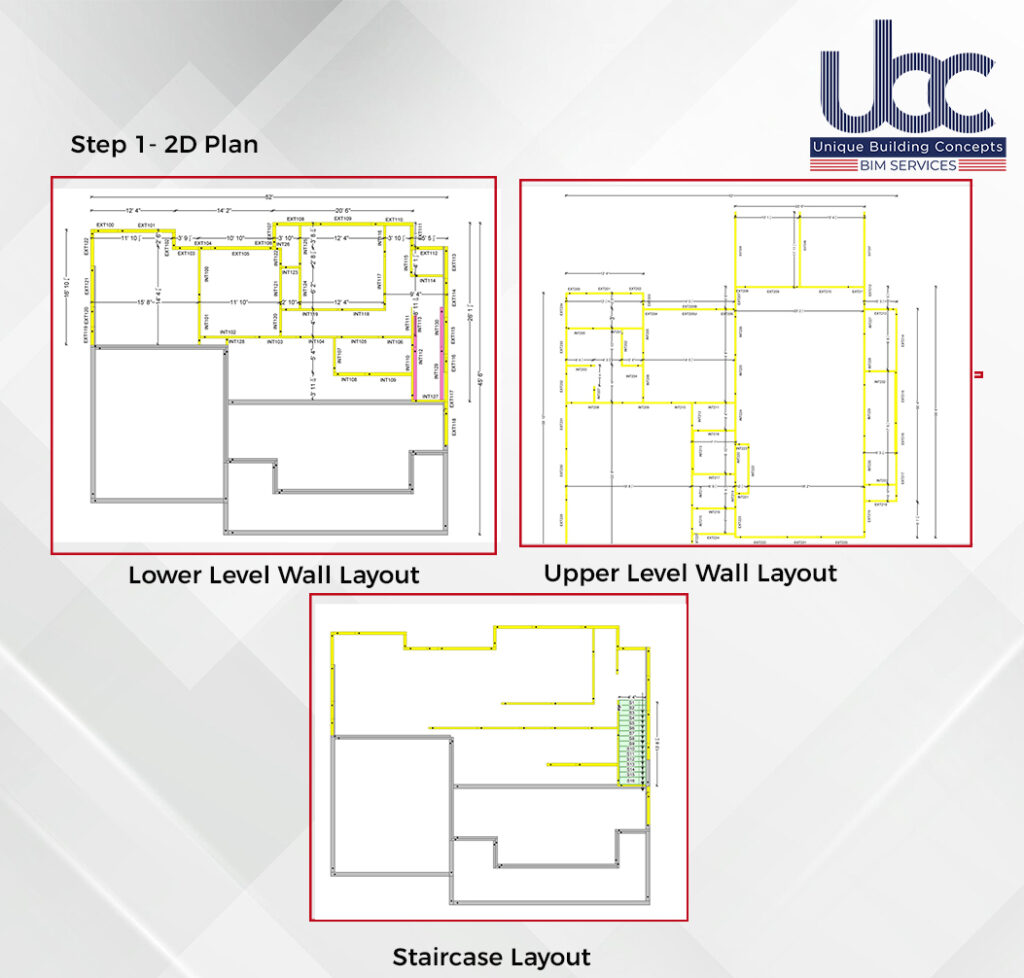

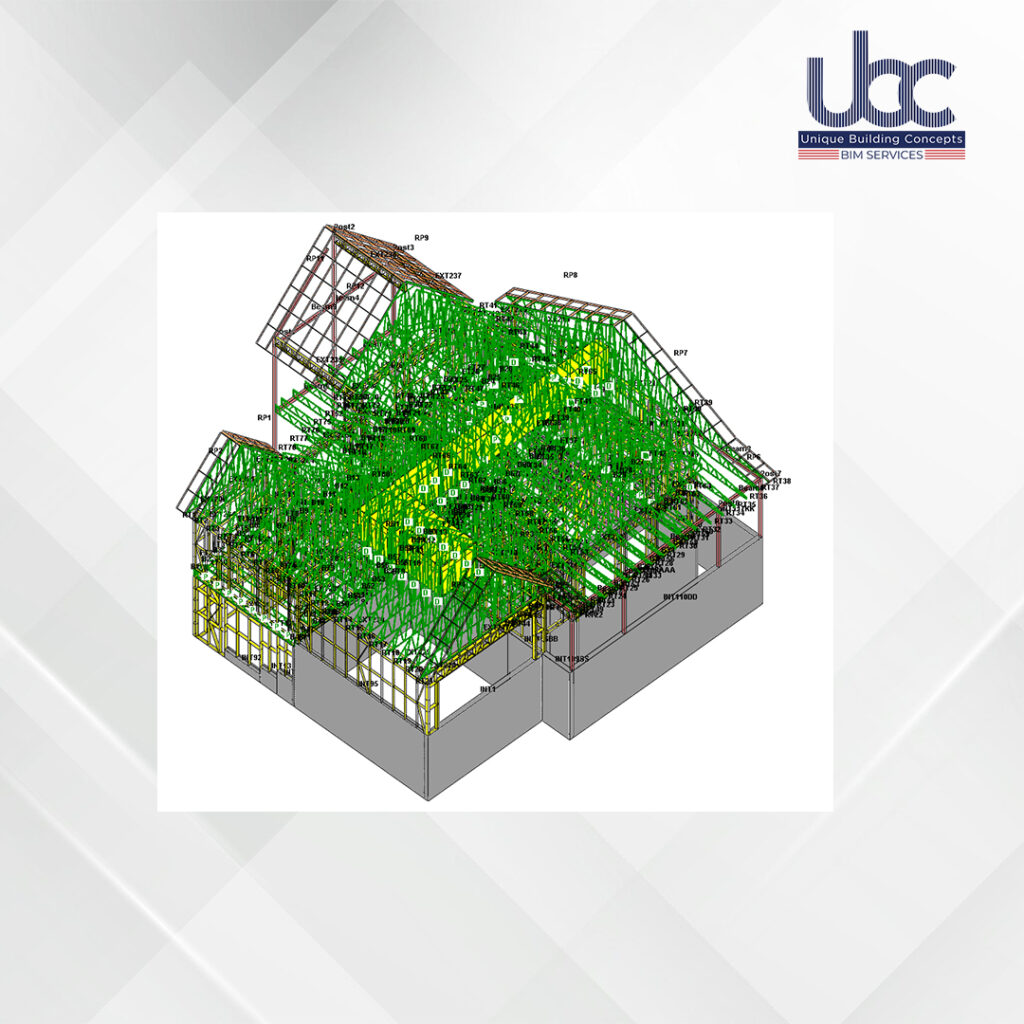

The project involved a two-storey residential building featuring a multi-slope roof, located on a terrain category site in Arkansas, USA. The natural topography presented varying elevations across the plot, requiring a strategic engineering approach. To address this, our team divided the plot into different levels and designed superstructures at varying basement heights to align with the site’s unique contours. This approach allowed for optimal use of the land while ensuring structural integrity and ease of construction.

Scope of Work

Building information modelling services from LOD 100 to LOD 500 in Arkansas, USA for both light gauge steel and timber framed structures. By managing the entire process, we maintained full control over quality, coordination, and accuracy at every stage. Remarkably, we completed the full cycle—from initial design to finalized production files—within just 4days.

Our comprehensive scope of work included:

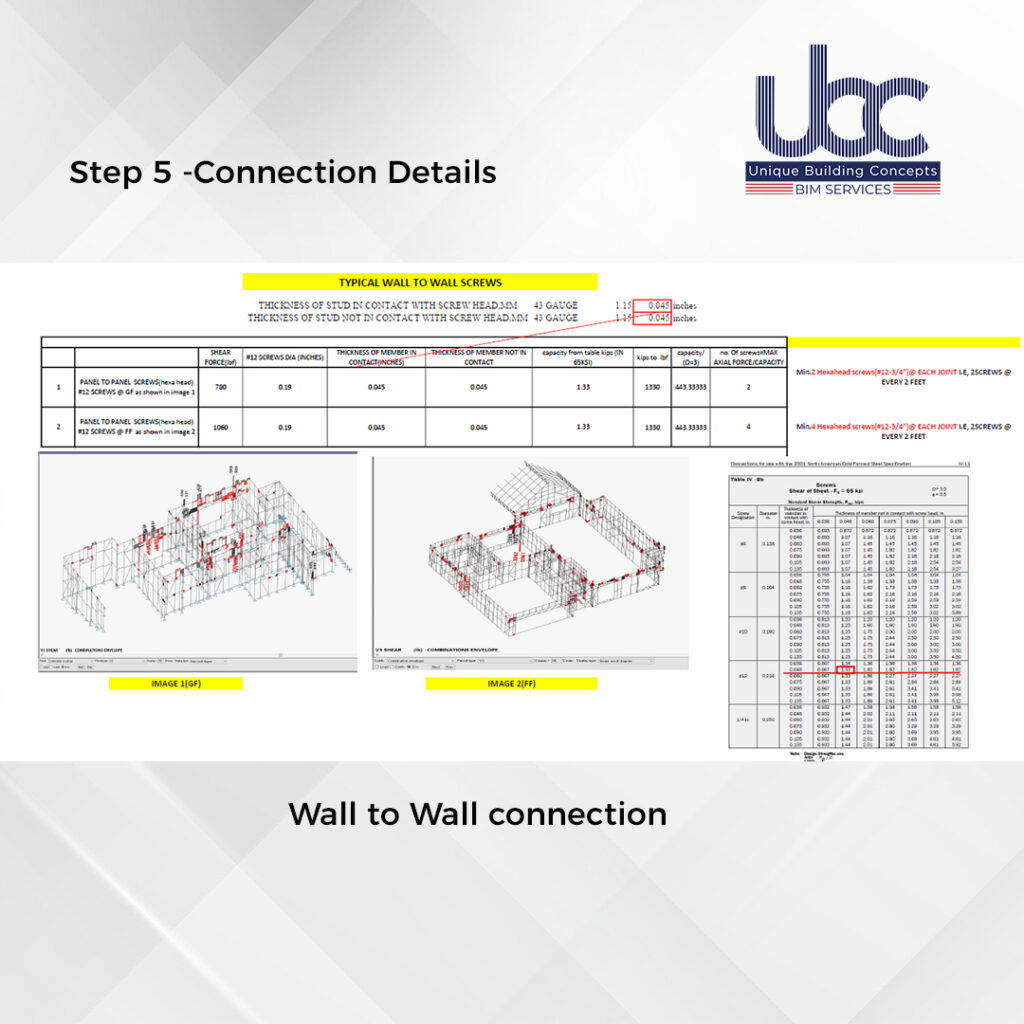

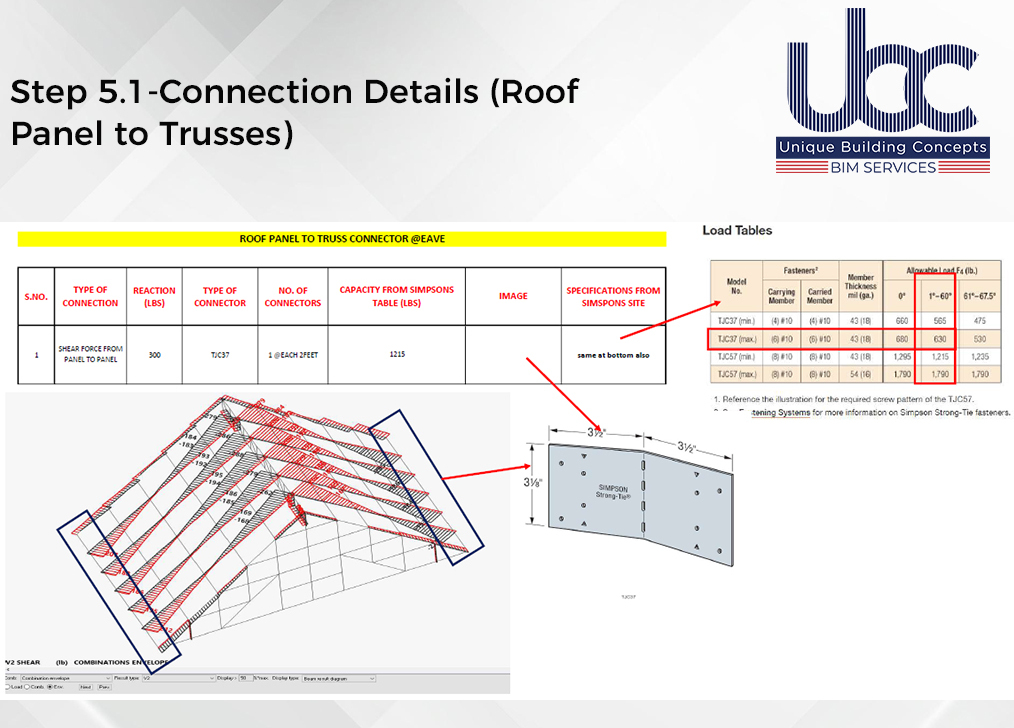

- Engineering

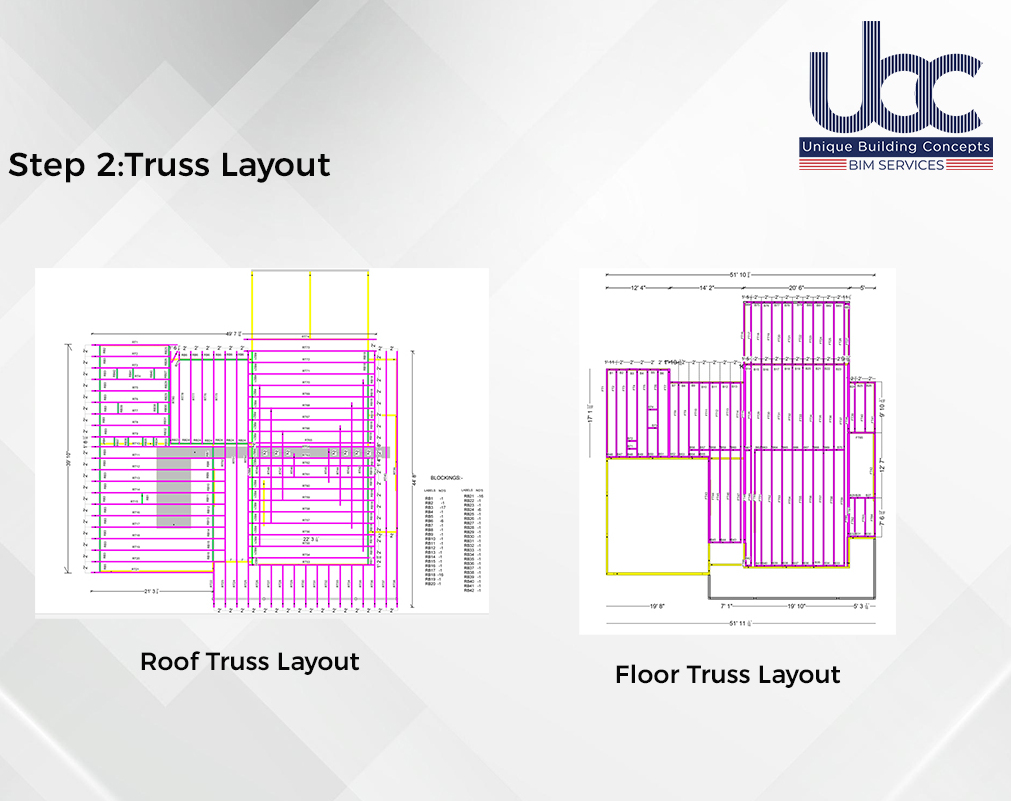

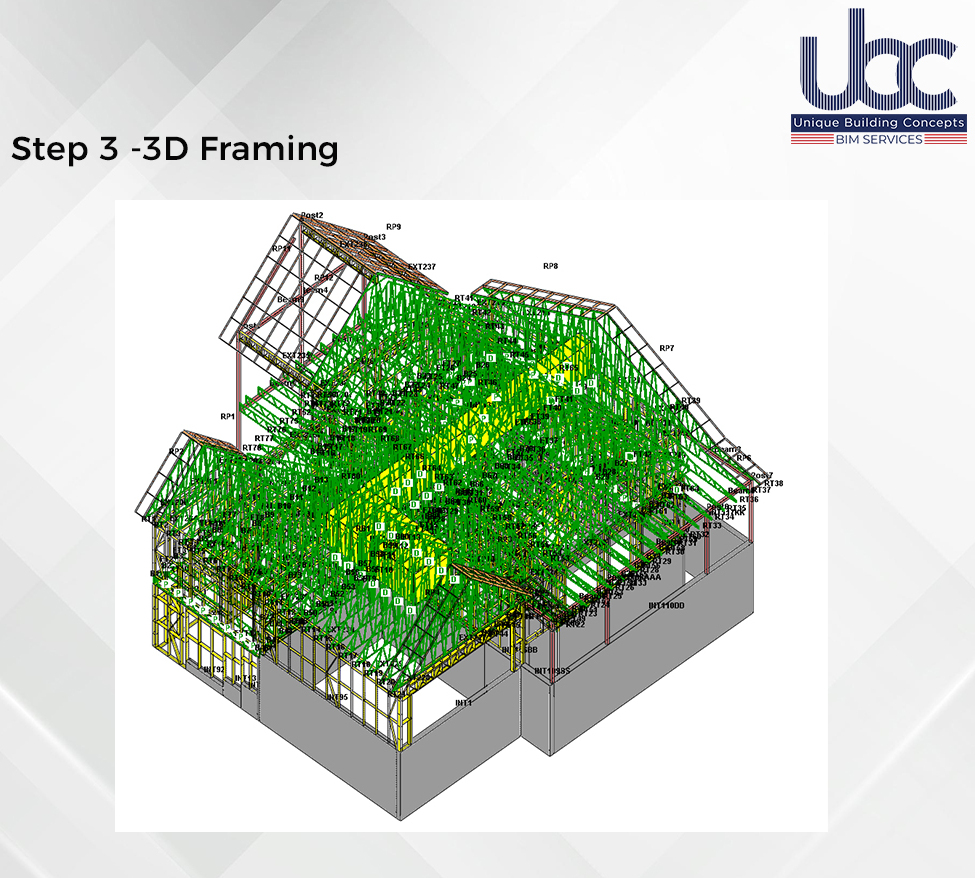

- Modeling

- Detailing

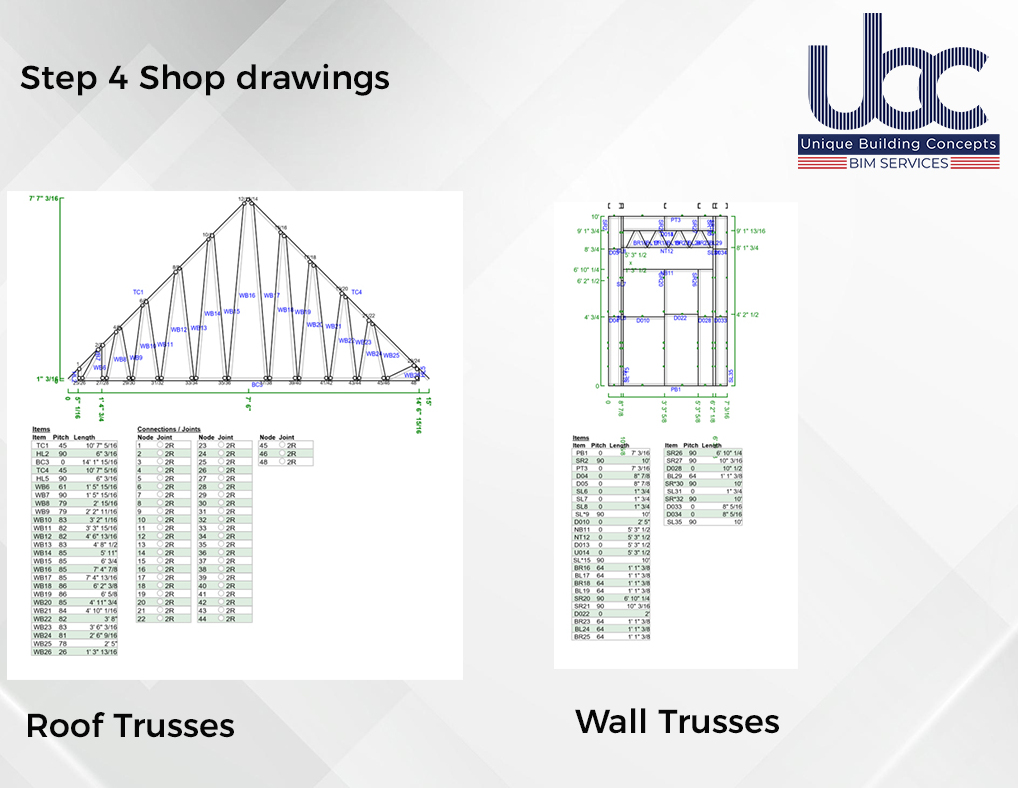

- Shop Drawings

- Production Files

Software

we utilized SCOTSTEEL software, which allowed us to execute detailed 3D modeling, precise structural engineering, and comprehensive detailing. The software’s advanced capabilities ensured that all elements were engineered with accuracy, minimizing errors and enabling smooth production workflows. Additionally, we integrated STRAP software for wall engineering, while SCOTSTEEL’s truss engineering module was employed to design and analyze the truss systems, ensuring structural integrity across all components.

Machine

The Scottsdale machine played a crucial role in transforming the digital models into accurate production files and fabrication-ready components. With its high level of precision, the Scottsdale machine ensured that each framing element was manufactured to exact specifications, streamlining the assembly process on-site. After completing the detailing and production process, the .rf output files were generated and promptly sent to the client, enabling a smooth and efficient fabrication workflow.

Why UBC?

This project exemplifies UBC’s expertise in rapid turnaround time, fully coordinated engineering solutions—even on challenging sites. Our integrated workflow, advanced technology, and experienced team enable us to turn complex designs into reality in record time, providing clients with efficient and reliable outcomes they can trust. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in the Arkansas, USA.