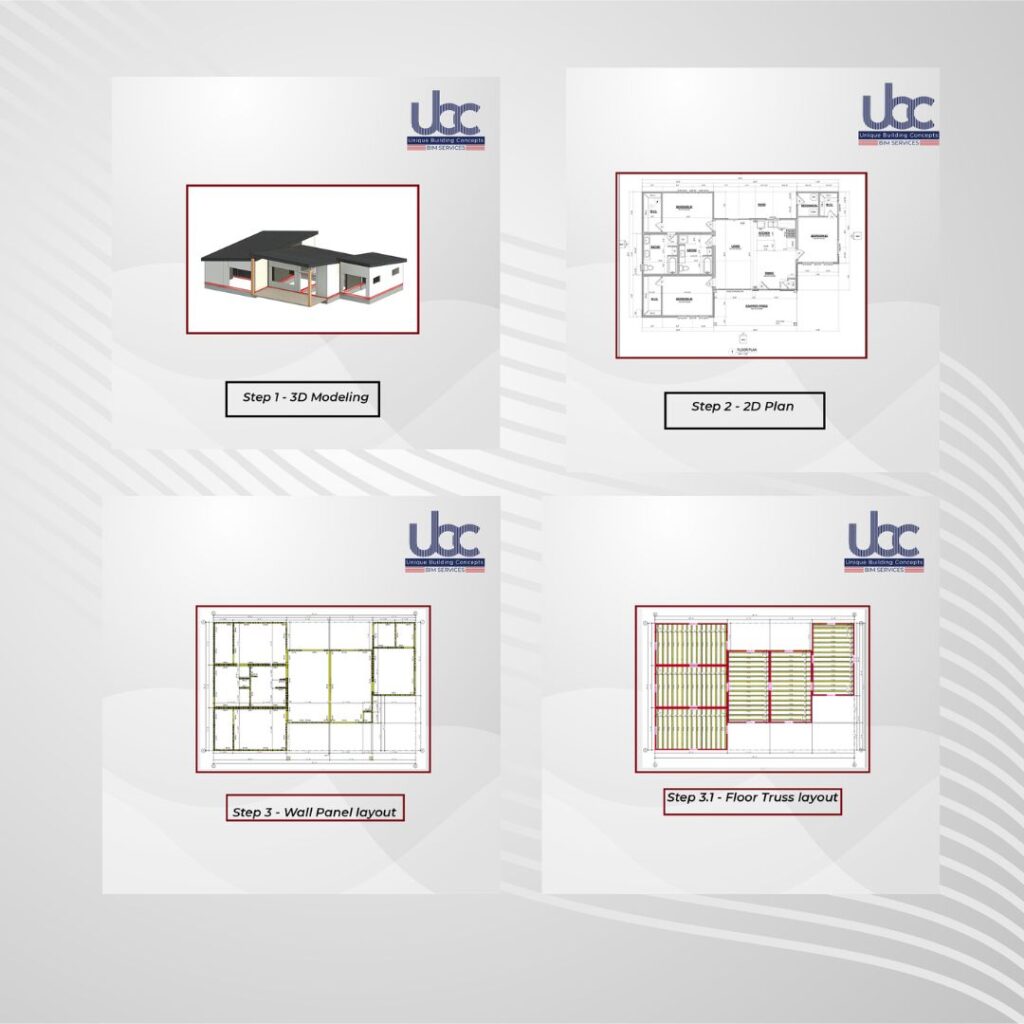

Project Overview

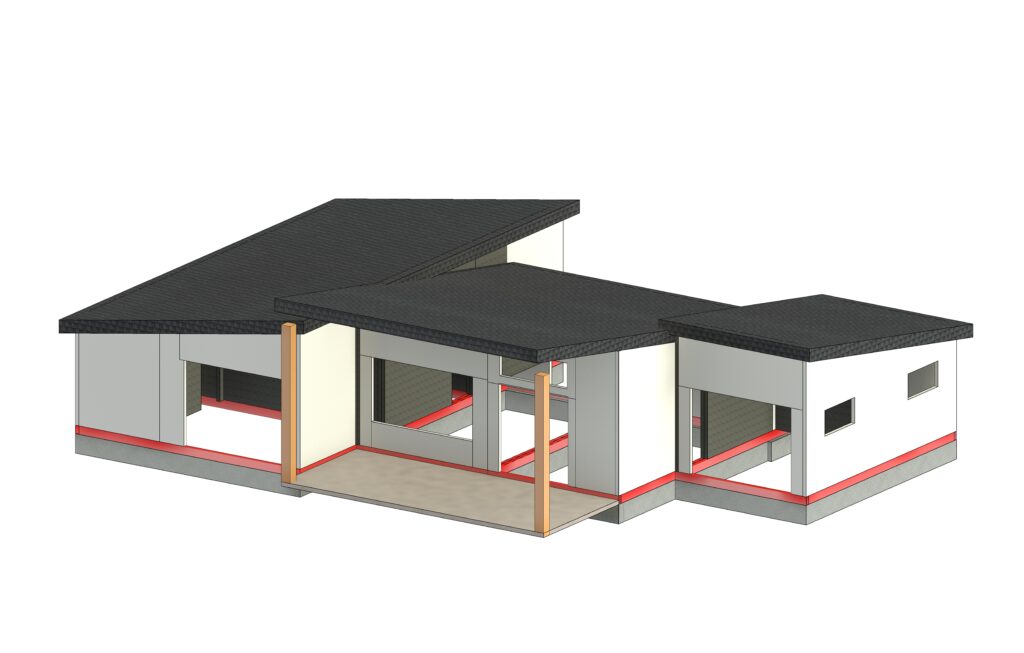

Our latest 1-storey residential building project in Idaho, USA of area 1633 sq. ft. showcases our commitment to accuracy, performance, and constructability. At UBC, we continue to push the boundaries of modern construction by integrating advanced design tools, hybrid structural systems, and CNC-driven manufacturing. This single-storey residential building features a mono roof design and is engineered using a hybrid structural system that integrates Light Gauge Steel Framing (LGSF) with Hollow Structural Sections (HSS). This combination enhances the structure’s overall strength, stability, and load distribution efficiency, making it both durable and highly reliable for long-term performance. Building information modelling services from LOD 100 to LOD 500 in Idaho, USA for both light gauge steel and HSS framed structures.

Scope of Work

- Engineering

- 3D Modeling

- Detailing

- CNC Production Files

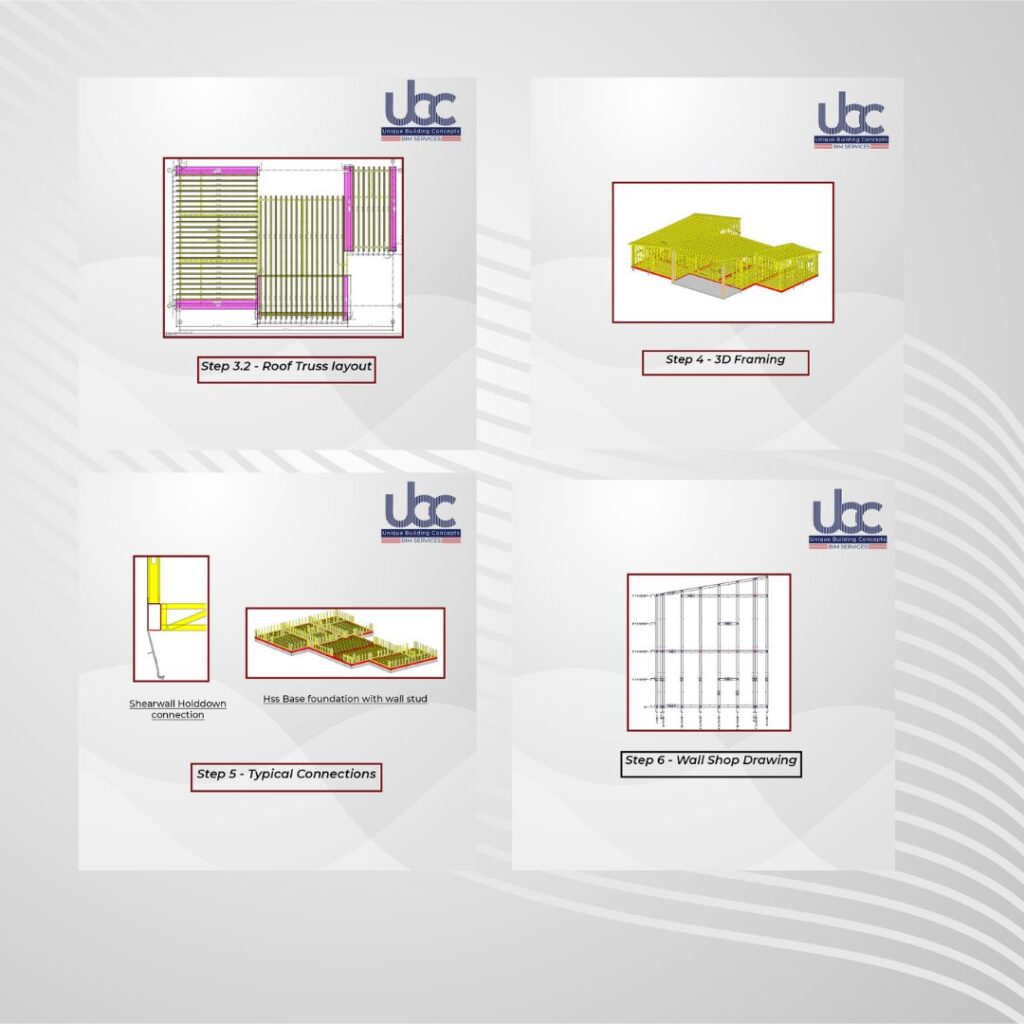

Key Structural Aspects

This project stands out due to its robust hybrid framework:

LGSF + HSS System

By combining LGSF panels with HSS members, the structure achieves high strength and durability while maintaining lightweight benefits ideal for fast installation and long-term performance.

Stem-Wall Foundation Integration

The building is anchored on a stem-wall foundation, providing superior support and enhancing lateral stability.

STHD14 Hold-Downs & Seismic Transfer

To meet seismic performance requirements, we used:

- STHD14 hold-downs

- Shear wall hold-down connections

These ensure reliable transfer of seismic forces directly to the foundation, improving overall safety and code compliance.

Software Used

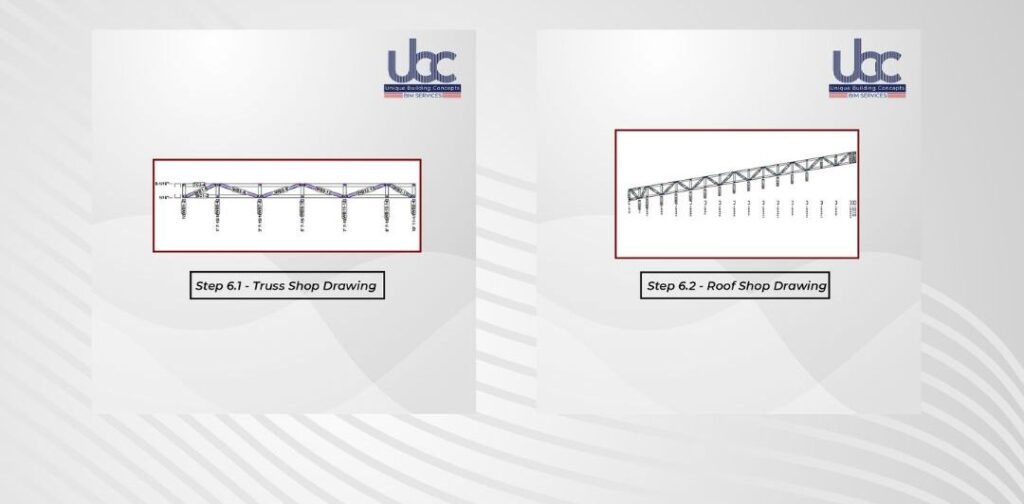

Revit MWF Strucsoft was utilized in this project to deliver highly intelligent and automated modeling capabilities, ensuring every framing element was generated with precision and efficiency. The software’s advanced rule-based engineering enabled seamless creation of LGSF wall, floor, and roof assemblies, reducing manual errors and enhancing design accuracy. Its automated framing tools allowed us to quickly convert architectural models into fully engineered framing layouts, while the integrated clash detection and connection detailing features ensured smooth coordination across all disciplines. With MWF Strucsoft, we were able to produce clear, installation-ready shop drawings and accurate material lists, supporting a streamlined workflow from design to CNC production.

Machine Used

The FrameCAD machine played a crucial role in delivering high-quality Light Gauge Steel Framing (LGSF) components with exceptional CNC precision. Its automated manufacturing system converted our engineered models and production files directly into accurately formed steel members, ensuring consistent dimensions, clean punch patterns, and precise bends. This level of accuracy not only reduces on-site errors but also speeds up installation and improves overall structural performance. By using FrameCAD, we ensured that every framing element met exact specifications, supporting a smooth transition from digital design to physical construction.

Conclusion

This project exemplifies UBC’s ability to execute technically complex residential structures using a fully integrated BIM-to-manufacturing workflow. The hybridization of LGSF and HSS allowed us to achieve superior axial, lateral, and flexural performance while optimizing member weight and material efficiency. Through Revit MWF Strucsoft, we maintained stringent control over framing geometry, connection logic, load paths, and constructability—ensuring the model accurately reflected real-world behavior. The transition from engineered framing layouts to CNC-ready production files enabled the FrameCAD system to fabricate components with tightly controlled tolerances, reducing field variability and installation deviations. The incorporation of stem-wall foundations, STHD14 hold-downs, and robust shear wall anchorage systems ensured compliant seismic load transfer and enhanced global structural stability. Overall, this project demonstrates UBC’s technical strength in delivering high-precision, code-compliant, and installation-optimized hybrid structures by leveraging advanced software, engineered detailing, and automated fabrication technologies. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures, Foundation design and EOR stamping Services in majority of states in Idaho, USA.