Project Overview

UBC BIM Services is proud to spotlight a compact yet highly efficient 504 sq. ft. hybrid (cold form steel/Red Iron) modular building in Elko, Canada featuring a gable roof with scissor trusses. Designed with both functionality and performance in mind, this structure exemplifies modern modular construction by blending robust materials with smart engineering. The superstructure utilizes Light Gauge Steel Framing (LGSF) for precision and durability, while the base is reinforced with Red Iron/ Structural Steel to enhance load-bearing capacity and provide a stable foundation. This hybrid configuration ensures strength, safety, and long-term reliability, making it suitable for diverse climatic conditions including high winds and heavy snowfall.

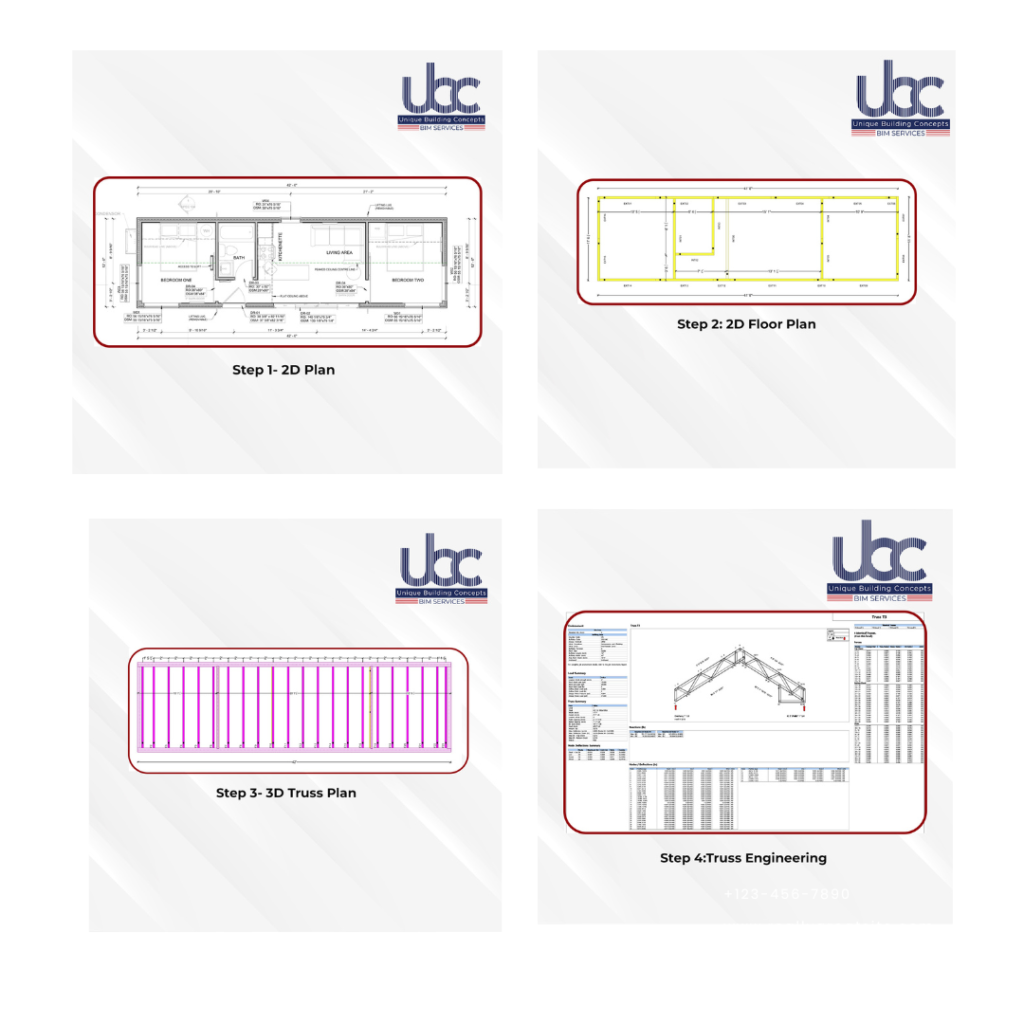

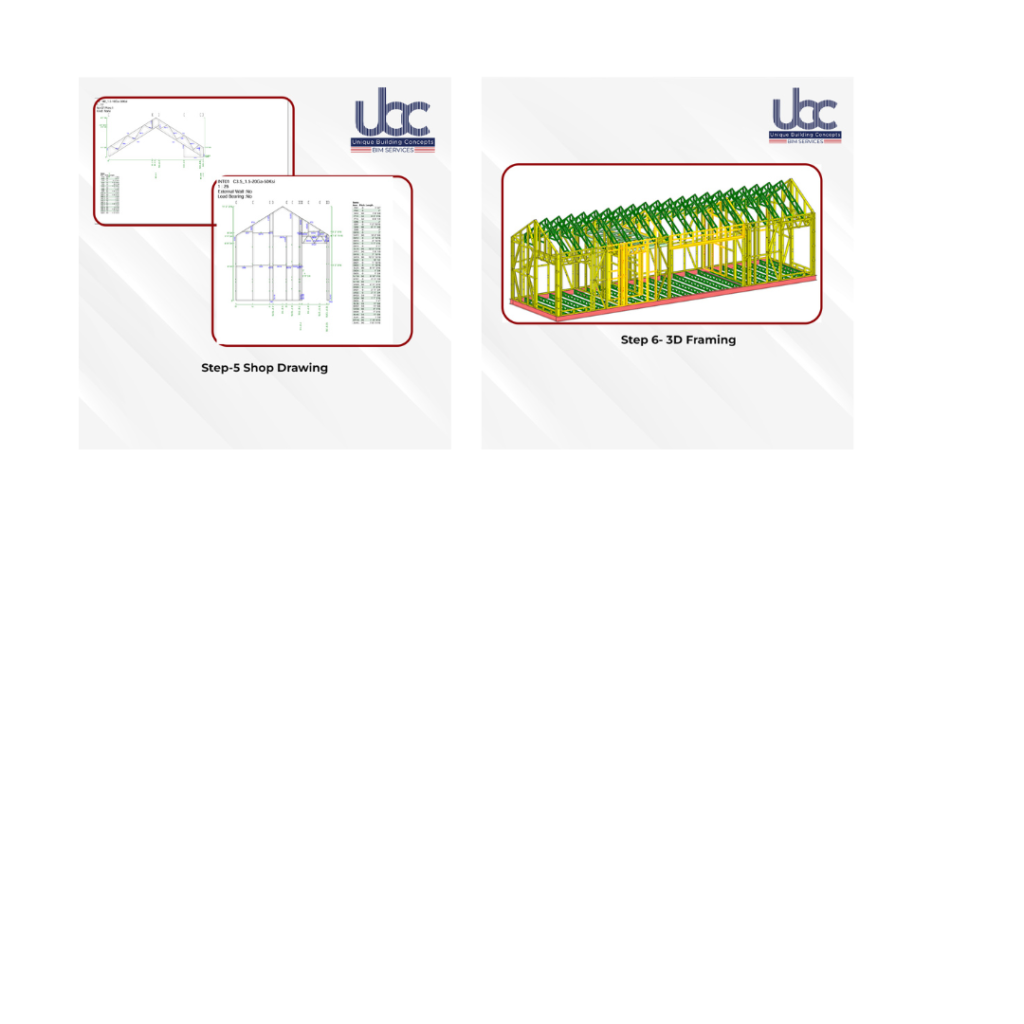

Scope of Work

The scope of work for this project included full-cycle support: engineering, detailing, and production file, all executed within 10-day timeline. UBC’s team meticulously engineered the structure to meet stringent design parameters and structural integrity standards. Following this, detailed panel and truss layouts were developed to align with production and installation needs. CNC-ready files were then generated, allowing seamless transition from design to fabrication with minimal iteration. Building information modelling services from LOD 100 to LOD 500 in Elko, Canada for both light gauge steel and timber framed structures

Software Used

All detailing work was executed using Scotsteel, a powerful software tailored for light gauge steel design. Scotsteel enabled high-precision modeling of both wall and truss systems, including the complex geometry of the scissor trusses used in the roof. Its intelligent toolset allowed for accurate clash detection, optimized material usage, and smooth integration of Red Iron/ Structural Steel supports all while aligning with Scottsdale machine requirements.

Machine Used

Fabrication was carried out using Scottsdale Construction Systems, ensuring precision manufacturing and consistent quality. The compatibility between Scotsteel software and the Scottsdale machine allowed UBC to generate reliable CNC files and produce framing components with exacting tolerances. This streamlined workflow eliminated manual errors and significantly reduced production time, making it possible to complete the entire project within just 10 days.

How UBC Simplifies Pick and Drop in Modular Construction?

A standout innovation in this project is the pick & drop method. The modular unit was fully prefabricated off-site, with lifting hooks pre-attached to the base of the Red Iron/ Structural Steel structure. This allowed the entire building to be transported and installed in one seamless operation using a crane. The pick-and-drop technique significantly reduced on-site labor and installation time, which not only enhanced safety but also improved overall project logistics.

The pick & drop methodology is rapidly gaining traction in the construction industry, especially for modular and remote-area builds. By eliminating most of the on-site assembly, it reduces costs, shortens construction timelines, and minimizes environmental impact. This project stands as a prime example of how modern modular construction, combined with advanced prefabrication and smart installation techniques, is reshaping the future of building.

Advantages of modular unit construction

- Increased Efficiency: Modular construction streamlines the building process.

- Reduced Errors: It has high precision which minimizes mistakes.

- Sustainability: Less waste and environmental impact.

Why UBC?

UBC continues to lead in modular innovation by integrating hybrid materials like LGSF and Red Iron, delivering solutions that meet structural demands while offering unparalleled flexibility and speed. This project exemplifies our commitment to efficient, modern construction practices that align with the evolving needs of the built environment. services. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in the Elko, Canada