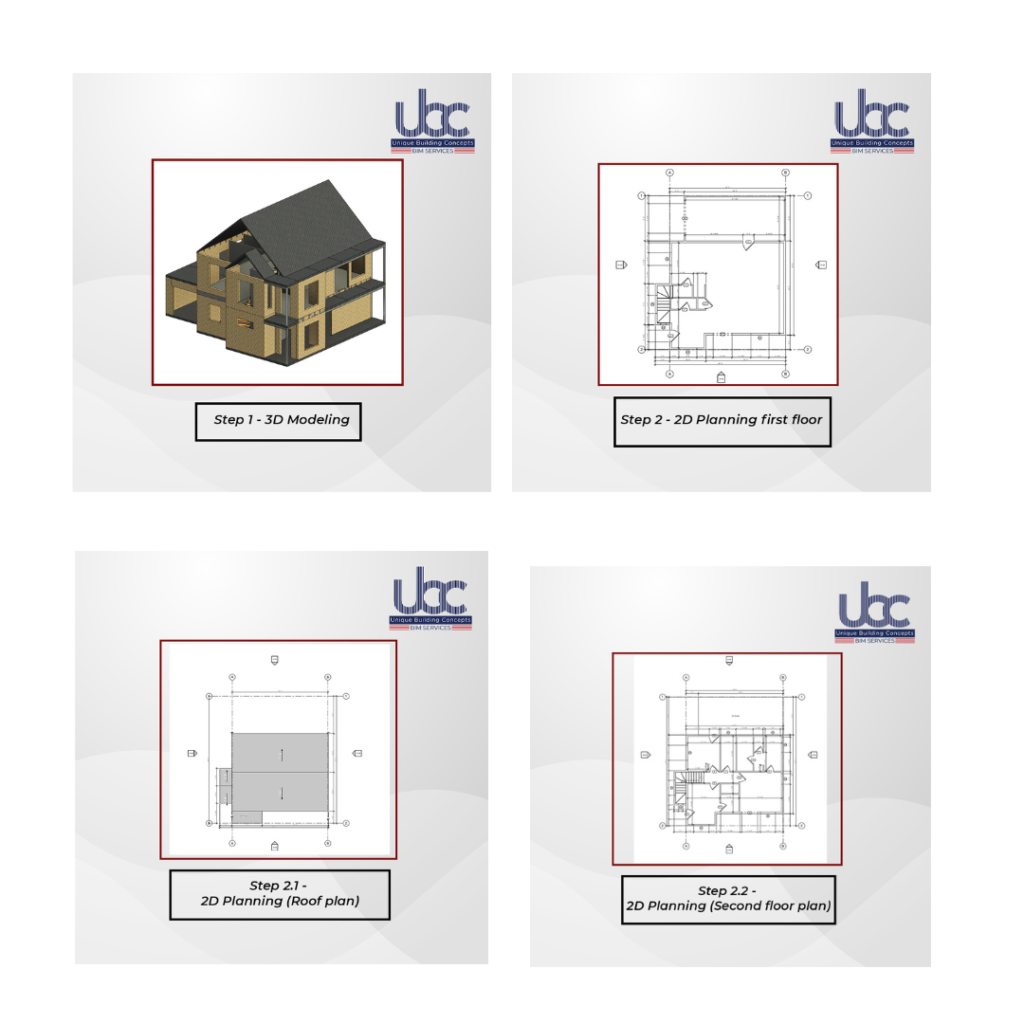

Project Overview

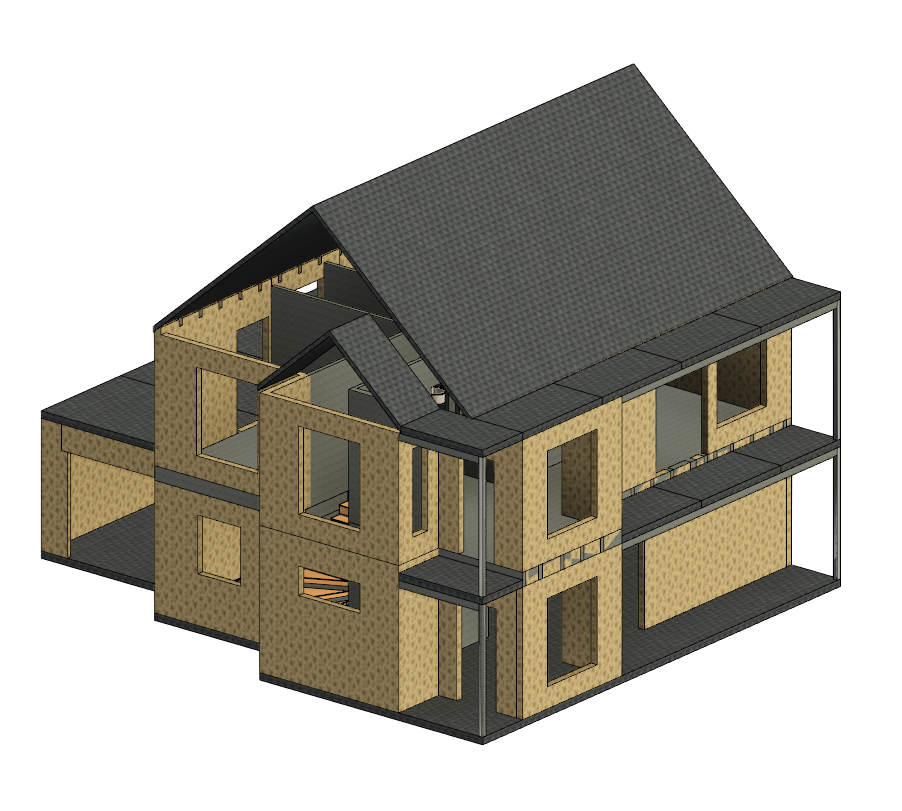

This residential project is of area 2,184.74 sq. ft. two-story residential structure in Austin,Texas engineered and detailed entirely in Light Gauge Steel Framing/Cold formed steel (LGSF/CSF). UBC was responsible for delivering a complete engineering and documentation package, covering everything from structural calculations to fabrication-ready production files. The building features high-strength, corrosion-resistant LGS members, custom-engineered roof and floor trusses, and an LGS-structured staircase designed to meet all local code and loading requirements.

Scope of Work

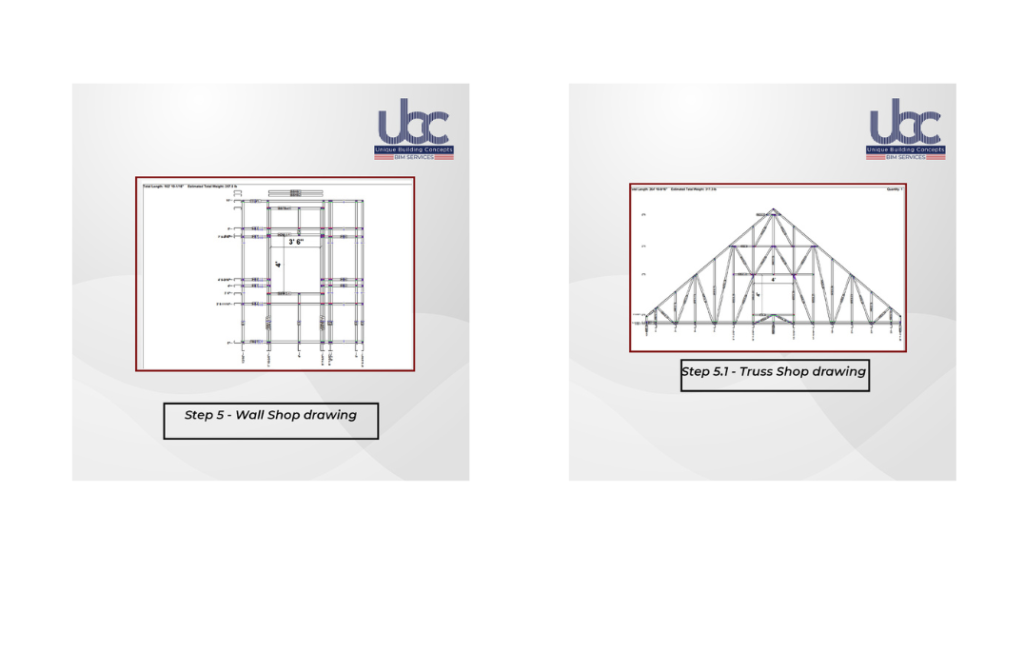

The scope of work included full structural analysis engineering, permit sets, 3D modeling,, and detailed shop drawings for walls, floors, roofs, and stairs. Each LGS component was documented, including, fastener schedules. The final output also included BOMs and CNC-compatible production files tailored for the FRAMECAD manufacturing system, ensuring seamless transition from 3D model to site execution. Building Information Modelling services from LOD 100 to LOD 500 in Texas, USA for both light gauge steel and timber framed structures

Software Used

To meet the project’s timeline and advanced technical requirements, team utilizes FrameCAD Detailer served as the primary modeling environment for both 3D architectural modeling, framing and FrameCAD Structures for structural components, allowing us to build and complete the project. FrameCAD Detailer was used to generate precise Light Gauge Steel Framing (LGSF) elements, enabling automation of panelization, member sizing, and rule-based connections based on local building code parameters.

Our workflow included load path analysis, framing optimization, particularly critical in areas of geometric complexity such as the staircase and roof design One of the key technical challenges of this project was the design and detailing of a fully LGSF staircase, without the use of any hot-rolled or conventional steel components. This required rigorous engineering to ensure code compliance for live loads, deflection criteria, vibration control, and fire resistance. The stair stringers, treads, risers, and landings were all constructed from custom-formed LGS members, each engineered with precise gauge, shape, and hole Punching pattern to meet strength and serviceability requirements.

FrameCAD Software enabled real-time coordination across the structural framing and architectural model, reducing spatial conflicts and ensuring accurate alignment of the stair structure with adjacent walls and floor systems. Each stair component was tagged with exact manufacturing data including cut lengths, hole punching patterns, and fastener types.

Machine used

Final outputs included CNC-ready production files fully optimized for FRAMECAD machine, allowing seamless offsite fabrication. The staircase framing, like all other LGS elements, was fed directly into the FRAMECAD Machine ensuring high-speed, zero-error manufacturing. This integration dramatically reduced on-site assembly time while maintaining the structural integrity and safety standards required for residential occupancy.

Conclusion

This Texas-based residential project showcases UBC’s capability to deliver high-performance, code-compliant cold formed steel (CFS)solutions under tight deadlines. By leveraging advanced tools like FrameCAD Detailer,FrameCAD Structures along with seamless integration with FRAMECAD machine, UBC ensured a fully engineered, precisely detailed, and fabrication-ready output. From complex stair design to optimized framing layouts, the project highlights our commitment to speed, accuracy, and innovation in offsite construction—setting a benchmark for future LGSF-based residential builds.UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in the Texas, USA.