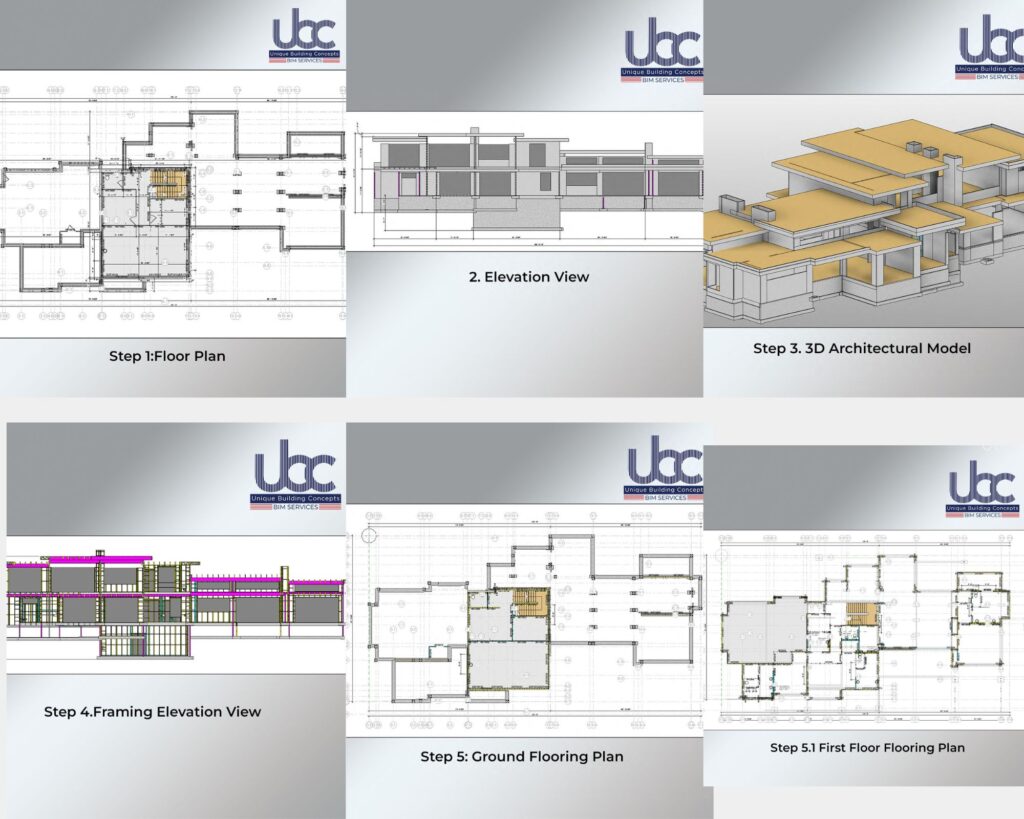

Overview

Team UBC delivered high-quality engineering, detailing, and production solution with unmatched speed and precision. Our recent project multi-Storey residential custom Building home/BIM services in Utah U.S.A of area-9,850 sq. ft.. It highlights our expertise in LGSF and hybrid construction techniques. Designed to withstand 110 mph wind speed and a 135 psf ground snow load, this project exemplifies efficient execution under stringent structural requirements.

Project Summary

This multi-story Residential BIM structure located in a high snow zone condition required a robust hybrid framing system with combination of LGSF and Red Iron. To meet engineering and constructability demands, we used:

- Profiles for LGSF: 362S162 and 600S162 in 33/43/54 gauges

- Roof System: Stepped flat slab roof with deck sheeting and concrete

- Engineering Scope: Stamped documents for permitting

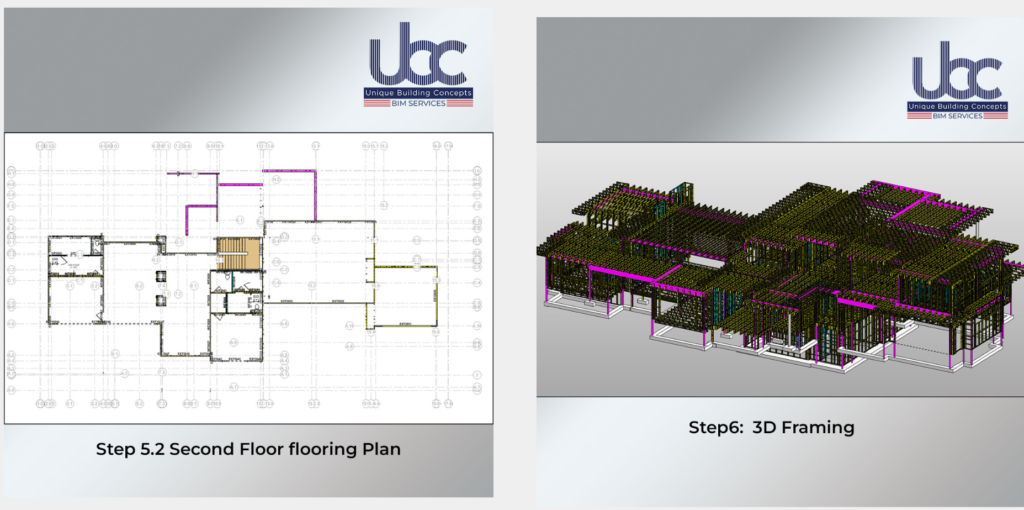

Software

UBC team used Revit MWF to create precise framing layouts, elevations, shop drawing and connection details ensuring accurate and efficient detailing. This streamlined design process helps speed up the detailing work.

Machines

For this project, our team utilizes the Frame CAD machine to produce building components with high precision. It automates the process of cutting, bending, and assembling light gauge steel into the required shapes. This machine helps create detailed parts quickly, reducing errors and saving time on-site.

Challenges and Solution

The UBC BIM team faced the challenge of supporting the additional weight for high snow drift conditions in Utah, snow loads can vary widely from 20 psf in lower areas to over 200 psf in the mountains. For our project, we had to design a structure to withstand a 135 psf ground snow load, which is much higher than typical Residential BIM services LGSF buildings. This created a big challenge for the UBC BIM team, as the extra weight from snow could weaken the structure if it is not properly supported.

To solve this we used a hybrid approach by combining Light Gauge Steel Framing (LGSF) with red iron steel. LGSF is lightweight and precise, but it alone wasn’t enough for such heavy snow loads. By adding Red Iron in key areas, and also adding Roof bracings and LGSF blockings we provided the extra strength needed without using too much material.

This solution ensured the building remained strong, cost-effective, and efficient. With careful BIM modeling and detailing, we created a structure that could handle the harsh winter conditions safely and reliably.

Why UBC?

UBC sets apart for its rapid turnaround, full-service solutions, and expertise in hybrid Structures using LGSF and Red iron. By delivering the entire engineering, detailing, and production scope within just a few days, we demonstrate our ability to coordinate teams efficiently, leveraging REVIT MWF to generate precise framing models and shop drawings, while FRAMECAD ensures accurate CNC output for production. This project highlights UBC’s capacity to execute complex high-load-bearing structures with speed and precision, making the go-to choice for both single-story homes and multi-level commercial buildings that require engineered solutions delivered fast and flawlessly.