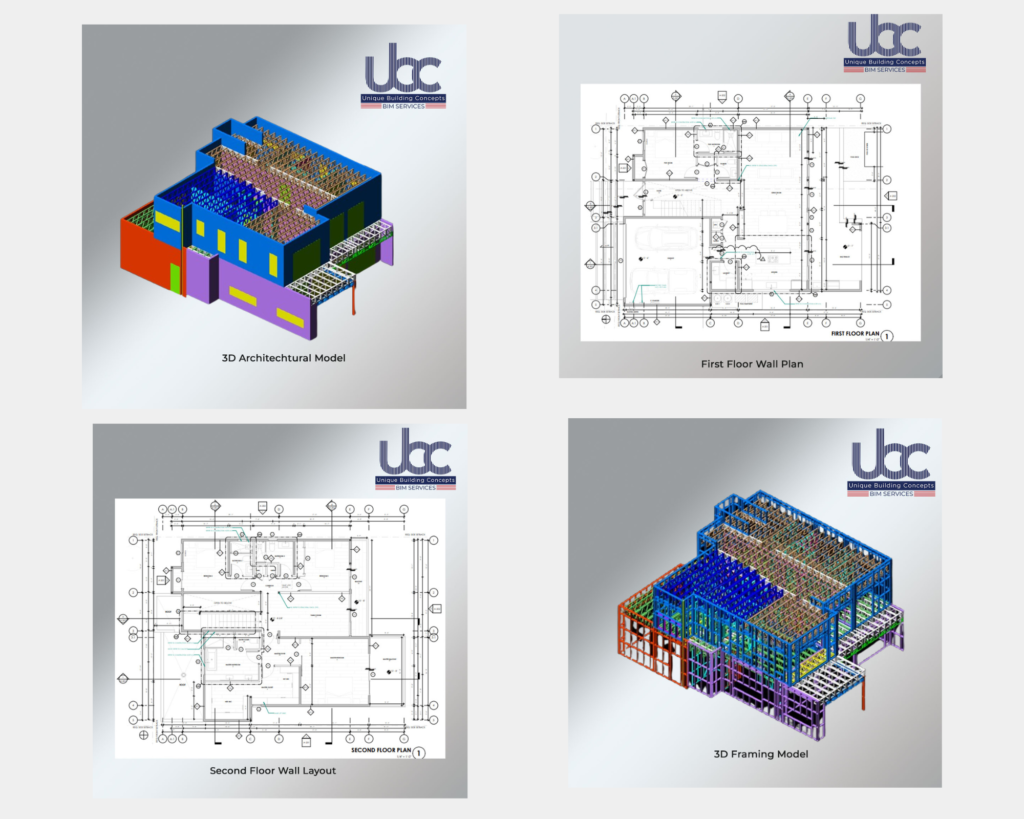

Overview

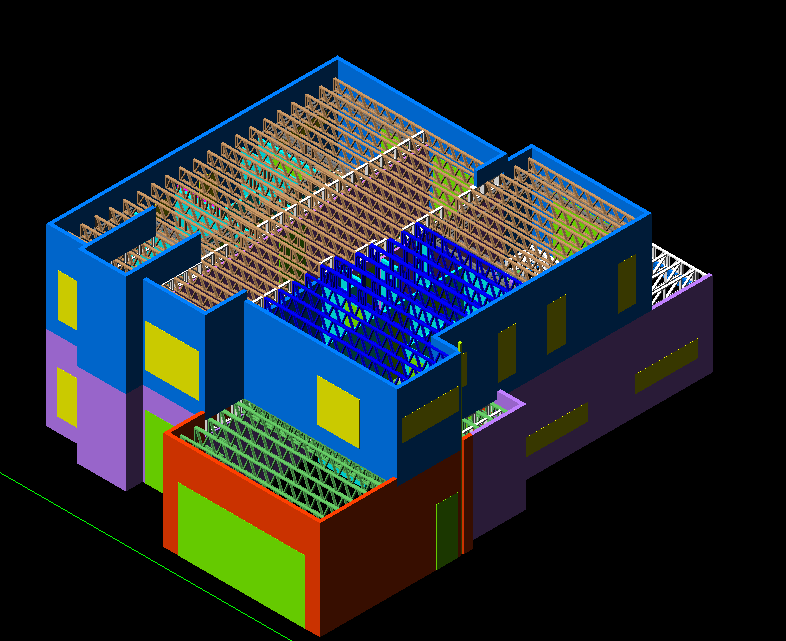

UBC successfully executed the engineering, detailing, and CNC production for a 4,150 sq. ft., two-storey residential LGSF custom single-family building in Florida, USA. Designed to withstand hurricane-force winds of up to 200 mph, this project demonstrates our expertise in Light Gauge Steel Framing (LGSF) for high-wind regions. Using Frame CAD software we ensured precise fabrication and accelerated construction timelines while maintaining compliance with stringent structural requirements.

Project Summary

This project required a robust, hurricane-resistant custom BIM solutions for unique construction solution LGSF structure with optimized framing profiles and an efficient load path to handle extreme wind pressures.

- UBC’s BIM engineering team provided expert BIM services for light gauge steel framing in Florida, USA, designing a robust structure that could withstand high winds and lateral loads, and delivering a strong superstructure and foundation design.

- LGSF Profiles Used:

– Ceiling Joists: 362S162-43-50

– Roof Panels: 600S162-43-50

– Interior & Exterior Walls: 362S162-33-50 & 600S162-43-50

– Roof System: Flat roof with reinforced bracing for wind uplift resistance.

- Engineering Deliverables: Stamped structural calculations and permit-ready documents.

Software

The UBC engineering team use Frame CAD Structures to ensure compliance with ASCE 7-22 wind load design requirements, minimize material waste, and optimize load distribution. By using Frame CAD Detailer, we developed precise framing models, shop drawings, and connection details, seamlessly converting framing layouts into machine-ready .rfy files to minimize production errors.

Machine

Team UBC BIM provided BIM detailing and modeling for a Frame CAD project in Florida, leveraging the machine’s high-speed, precision manufacturing capabilities. The automated LGSF production, with CNC-processed framing elements, ensured millimetre accuracy, optimized material usage, and minimized waste. Additionally, the pre-punched openings facilitated seamless MEP installations, accelerating on-site assembly and enhancing overall construction efficiency.

Challenges & Solutions

The team encountered two major challenges in this project. First, they engineered the building to withstand 200 mph wind speeds by creating continuous load paths with shear walls and tie-down anchors. They used deep-section LGSF (Light Gauge Steel Framing) profiles to increase rigidity and implemented roof diaphragm bracing and uplift connectors. Second, they optimized structural efficiency by designing redundant bracing systems to distribute wind loads evenly, incorporating high-strength blocking to minimize lateral deflection, and conducting BIM clash detection to optimize frame-to-foundation connections. This approach ultimately achieved a balance between structural integrity, material efficiency, and cost.

Why UBC?

UBC construction (unique building concepts) stands out with fast engineering, precise detailing, and CNC automation, ensuring projects are completed quickly and accurately. Our advanced Frame CAD-driven manufacturing enables high-speed, error-free fabrication. We specialize in wind-resistant LGSF solutions, making our structures ideal for hurricane-prone areas. With seamless BIM integration, we minimize field modifications and ensure smooth installation. This project is a perfect example of UBC’s commitment to delivering strong, safe, and high-quality LGSF structures with unmatched speed and precision. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in the state of Florida, USA.