Project Overview

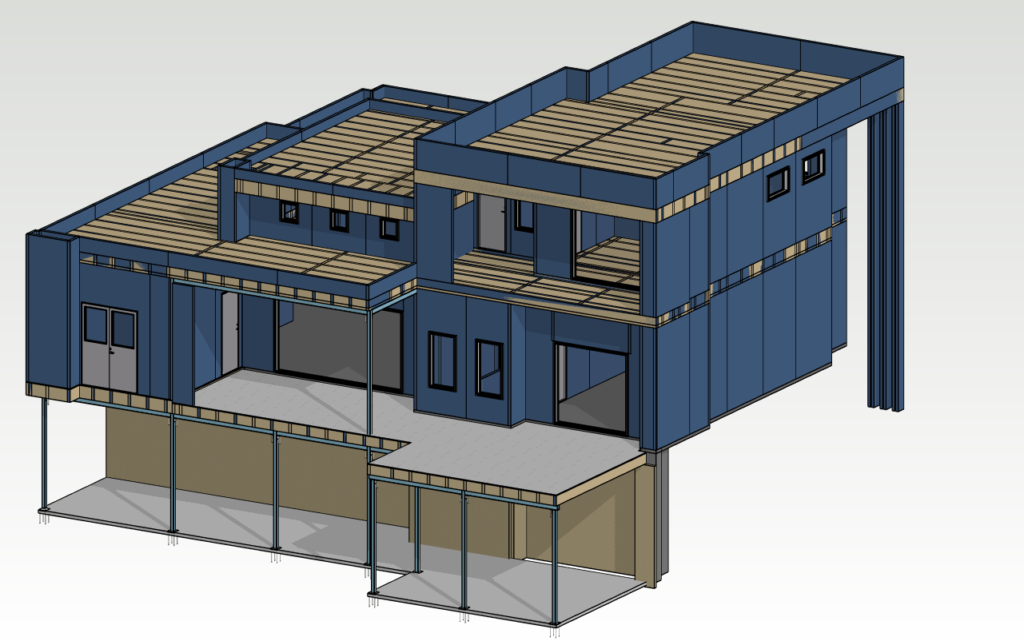

This 2-storey home building custom services using cold formed steel in Texas, USA was designed with a flat roof system and a crawl foundation to meet both functional and architectural requirements. The choice of a crawl foundation provided flexibility for services and insulation, while ensuring cost-efficiency compared to a full basement. One of the standout features of this building is the use of LGSF ladder columns that support the flat roof structure. These columns not only add strength but also allow for clean design lines, reducing bulky structural elements that could compromise aesthetics. The hybrid approach blends the efficiency of steel with conventional construction techniques, delivering a balance between modern innovation and practical usability. Building information modelling services from LOD 100 to LOD 500 in Texas, USA for both light gauge steel and timber framed structures.

Scope of Work

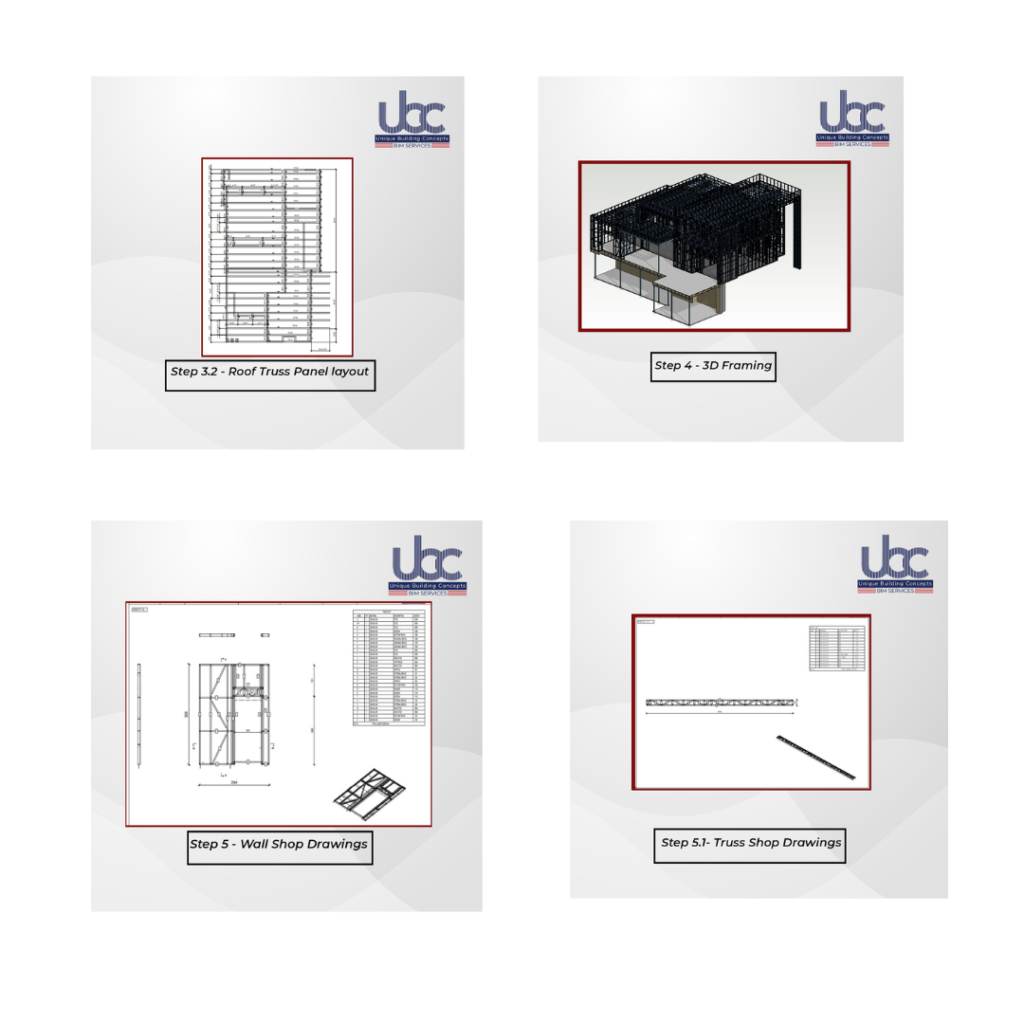

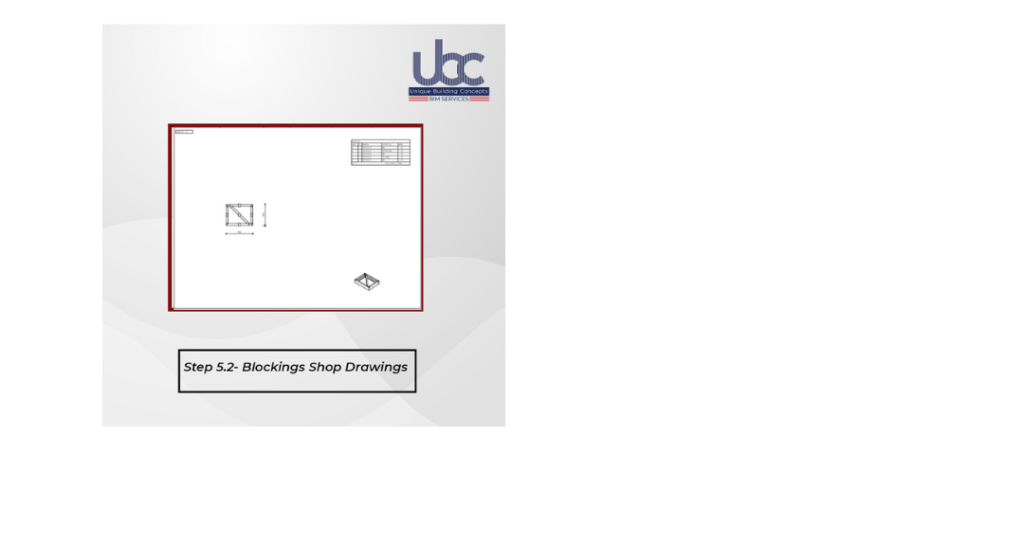

CNC Productions

The scope of work for this project encompasses complete engineering analysis, parametric 3D modeling, detailed shop drawing generation using cold formed steel for custom residential building, and CNC production file preparation. Using Vertex BD, the structure is modeled with precise geometry to reflect the LGSF system, ensuring accurate member sizing, connectivity, and alignment with fabrication standards. The detailing process includes wall, floor, and roof assembly, along with connection detailing for LGSF ladder columns and crawl foundation integration. Shop drawings are extracted directly from the model to maintain consistency between design and production. CNC output files are generated in compliance with the XHH roll-forming machine specifications, ensuring accurate punching, cutting, and notching operations during fabrication. This end-to-end technical workflow minimizes tolerance issues, reduces on-site adjustments, and delivers a build-ready solution optimized for both structural performance and constructability. This integrated workflow minimized iterations, reduced wastage, and ensured that the project was completed within strict timelines while maintaining the highest quality standards.

Key Highlights:

The hybrid design strikes a perfect balance between strength and efficiency. The integration of ladder columns enhances the load-bearing capacity while reducing material usage, reflecting our commitment to sustainable and cost-effective construction. Each detail—from foundation to roofing—was engineered to guarantee precision, ease of installation, and long-term performance.

Software Used:

For this Hybrid Residential Building, Vertex BD was utilized as the core BIM and detailing software, enabling precise 3D modeling, automated shop drawings, and CNC production files. Its intelligent parametric modeling allowed seamless integration of Light Gauge Steel (LGSF) ladder columns and timber elements, ensuring structural stability and aesthetic appeal. Vertex BD’s clash detection, custom profile management, and real-time updates streamlined coordination between engineering and fabrication, reducing errors and accelerating delivery, while its direct CNC integration ensured high accuracy and efficiency throughout the project lifecycle.

Machine Used:

For production, we utilized the XHH machine, known for its accuracy and efficiency in fabricating Light Gauge Steel components. By integrating the CNC files generated from Vertex BD, the XHH machine ensured that each framing element was manufactured with millimetre / Inch sub unit’s precision. This minimized on-site errors, accelerated assembly, and guaranteed a perfect fit during installation.

Conclusion:

This Custom Hybrid Residential Building project exemplifies the seamless integration of advanced engineering, precise software detailing, and efficient fabrication. By leveraging Vertex BD’s intelligent modeling capabilities and the precision of the XHH machine, the project achieved exceptional accuracy, reduced waste, and optimized construction timelines. The result is a structurally robust, aesthetically refined, and cost-effective building that reflects innovation in modern construction and sets a benchmark for future hybrid design projects. UBC offers permit sets, pre-bid packages with 3D BIM model along with bill of materials for project cost estimation, modeling and detailing services, engineering calculations for light gauge steel/cold formed steel/ timber framed building structures in Washington DC, USA.