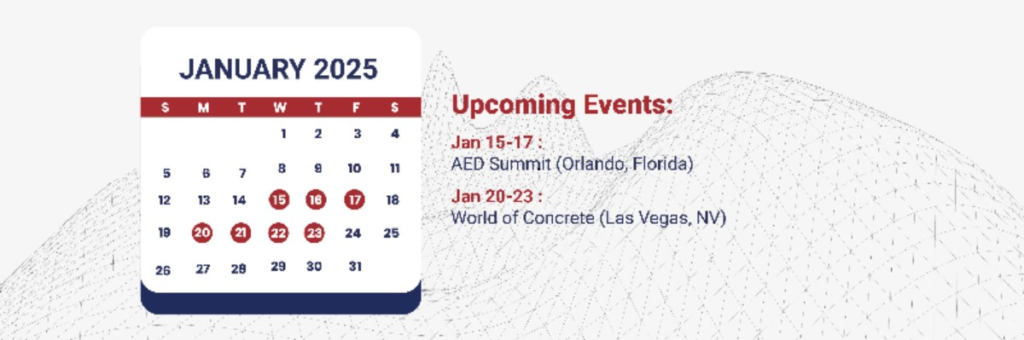

Upcoming Events

Company Events

Featured on Dave Cooper live show more updates please watch this video

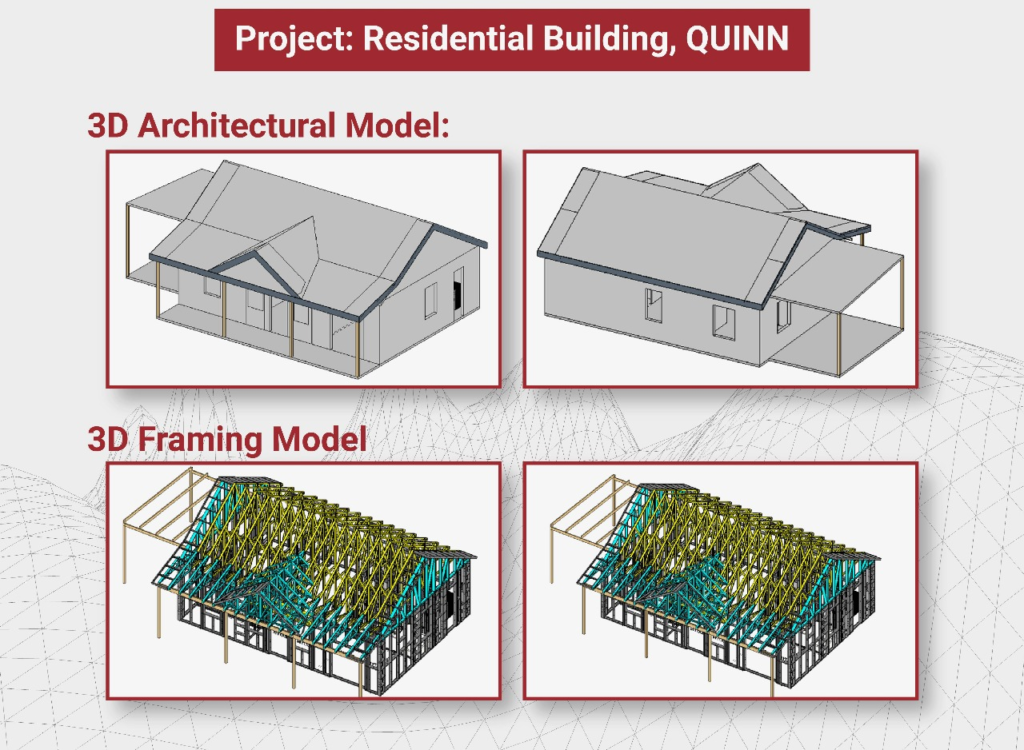

Project Of the Month

Project Details:

Title: QUINN

Location: Show Low, AZ

Project Size: 1125 SFT

Storey: SINGLE STOREY

Project type: Residential Building

Material Used: LGSF

Scope of work: MODELLING & DETAILING

Duration: 5 Days

Software: Revit

Machine used: FRAMECAD

Project description:

This single-storey residential project in Arizona, area 1,125 sq. ft. and showcases the potential of Light Gauge Steel Framing (LGSF) in modern construction. The scope involved comprehensive modelling and detailing, adhering to client specifications and mandatory standards for LGS profiles and connections. Utilizing advanced Revit software Advanced steel, the project was meticulously planned and executed within just five days, ensuring precision and efficiency.

The design incorporates profiles 362S162-43, 362S162-33, 600S162-43, and 600S162-33, delivering a structure optimized for durability and performance. Fabrication was executed on a Frame CAD machine, ensuring superior quality and seamless alignment with the detailed design. This project highlights the integration of cutting-edge technology and efficient processes, demonstrating innovation in residential construction.

Industry Insights

Insights on Cold-Formed Steel Framing’s Impact on Sound Control

Cold-formed steel (CFS) framing offers a unique blend of structural integrity, fire resistance and sound control. A new SFIA paper by Robert Grupe explores how to optimize CFS-framed structures for superior acoustic performance Read More

Technical Snippet

Truss Engineering in Scotsteel with 2’ inch Hat Profiles for High Wind Zones

Designing and engineering trusses in high wind zones requires precision, durability, and compliance with stringent safety standards. When using Scottsdale machines, incorporating 2’ inch hat profiles offers a robust solution for light gauge steel (LGS) trusses, especially in areas prone to strong winds.

Benefits of 2’ inch Hat Profiles in High Wind Zones

1.Enhanced Strength and Stability

Hat profiles provide excellent resistance to lateral forces, making them an ideal choice for high wind areas. Their structural design evenly distributes wind loads, reducing the risk of failure under extreme conditions.

2.Lightweight and Flexible

Despite their strength, 2’ inch hat profiles are lightweight, which reduces the overall load on the structure while maintaining flexibility to absorb dynamic wind forces without permanent deformation.

3.Precision Fabrication with Scottsdale Machines

Scottsdale’s automated roll-forming technology ensures high precision when producing hat profiles. This eliminates inconsistencies and results in trusses that fit perfectly during assembly, minimizing on-site adjustments.

4.Compliance with Wind Zone Standards

Using hat profiles in conjunction with Scottsdale’s SCOTSTEEL and SCOTSIM software allows engineers to model and simulate wind forces accurately. This ensures the trusses meet local and international wind load codes, providing peace of mind in high-risk areas.

5.Corrosion Resistance

In high wind zones, structures are often exposed to moisture and salt, especially in coastal areas. Hat profiles made from galvanized or coated LGS resist corrosion, enhancing their durability over time.

Key Design Considerations

- Truss Configuration: Optimizing the shape and spacing of trusses is essential for evenly distributing wind loads.

- Connection Details: Proper bolted or welded connections are critical to prevent weak points under high wind pressure.

- Anchorage: Trusses must be securely anchored to the structure to resist uplift forces during storms.

- Aerodynamic Design: Streamlined designs can help reduce wind resistance and the likelihood of structural damage.

Unique Testimonials

Contact us:

Email: Marketing@ubcbim.com, Website: www.ubcbim.com

Click here to Follow us on:

Facebook, Linkedin, Instagram, Youtube