UBC team outing = fun, laughter, and zero meetings! 🎉 A day well spent bonding, relaxing, and creating memories.

All dressed up and spreading Christmas cheer at the UBC office party! 🎄✨ The celebration got even more special with our charity visit to Telangana Government’s Sishuvihar for women and children welfare. Style, smiles, and kindness—that’s how UBC celebrates the season.

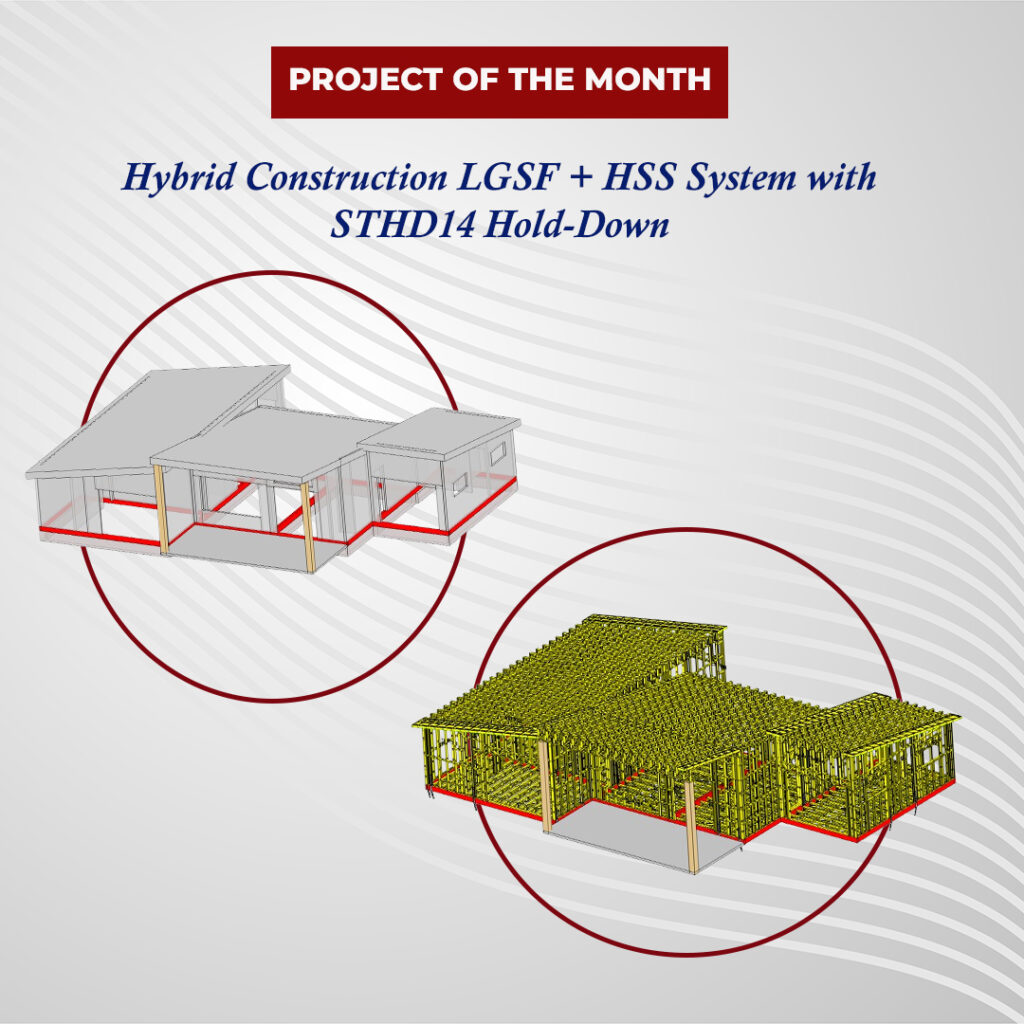

Project of the Month

Project type : Hybrid Residential Building

Area : 1633 sft

Roof : Mono Roof

Storey : 1-Storey building

Scope of Work : Engineering

3D Modeling

Detailing

CNC Production Files

Software : Revit Automation & Customization Training and Project Consultant MWF Structsoft

Machine : FRAMECAD

This project showcases a compact yet robust hybrid construction designed for performance, precision, and constructability. The 1-storey building, spanning 1,633 sft in Idaho, USA with a mono roof, integrates a hybrid structural system combining Light Gauge Steel Framing (LGSF) and Hollow Structural Sections (HSS) to achieve optimal strength and efficiency.

Our scope covered structural engineering, 3D modeling, detailed shop drawings, and CNC production files, ensuring seamless coordination from design through fabrication. The structure is supported on a stem-wall foundation and secured using STHD14 hold-downs, providing reliable shear wall hold-down connections for effective seismic load transfer to the foundation.

Advanced detailing ensured alignment with fabrication requirements, site conditions, and installation sequencing, minimizing rework and maximizing accuracy. This project highlights our expertise in delivering integrated hybrid solutions that combine engineering precision with constructible design—ready for efficient manufacturing and smooth on-site execution.

Industry Insights

Wildfires have long posed a severe threat to communities across Australia, destroying homes and taking lives.

At the 2024 CFSEI Expo in Tucson, Arizona, on May 21, Ken Watson, executive director of the National Association of Steel-Framed Housing, presented solutions for designing steel-framed buildings to withstand wildfire attacks in a special keynote address. Watson’s presentation at the annual Cold-Formed Steel Engineers Institute (CFSEI) conference underscored the critical role of cold-formed steel (CFS) in enhancing wildfire resilience while offering cost-effective and robust construction options. Read More

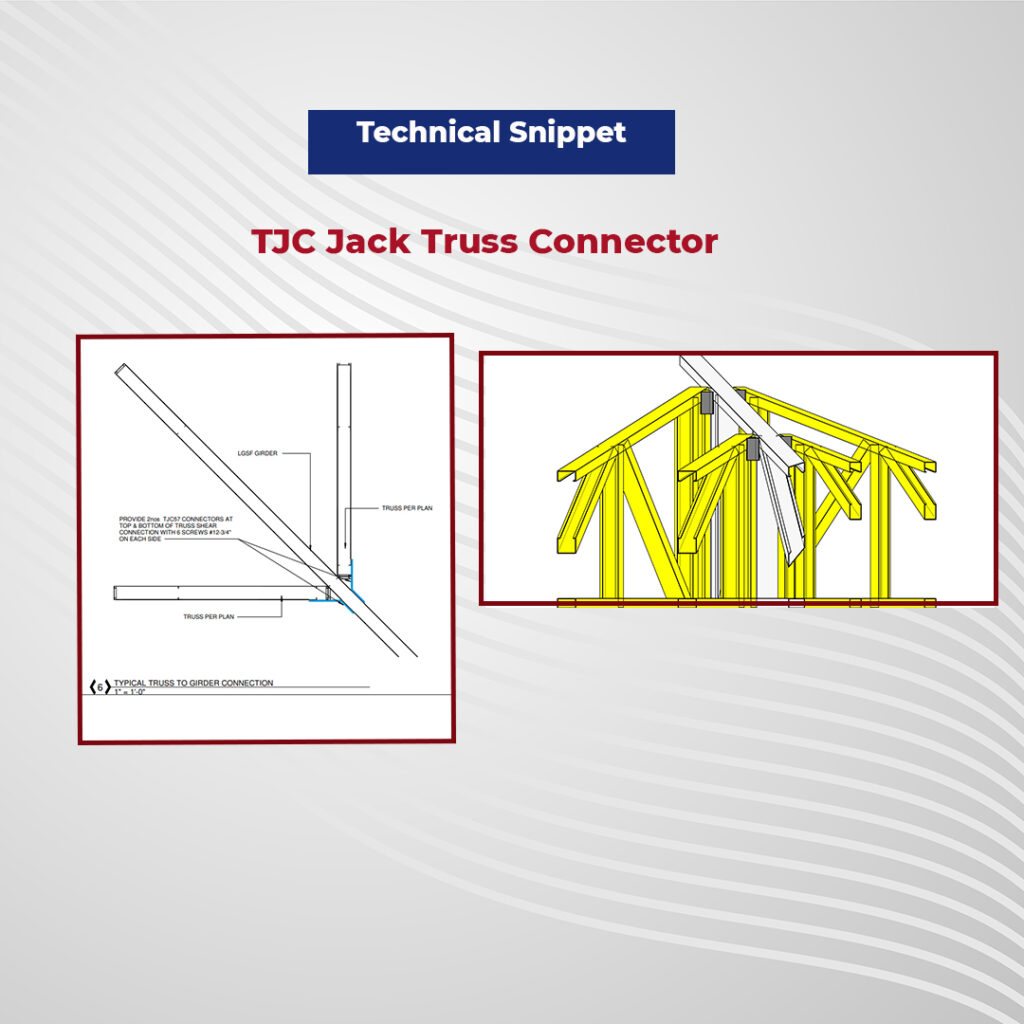

Technical Snippet

TJC Jack Truss Connector

TJC is a versatile connector for jack trusses. Adjustable from 0 degree to 85 degree (shipped with 67.5 bend). Nail hole locations allow for easy installation. Minimum nailing option on TJC37 provides faster installation and lower installed cost.

Product Details

Material – 16 ga.(54 mil)

Finish – Galvanized (G90)

Installation –

. TJC37 can be installed filling round holes only or filling round and triangle holes for maximum values.

. To reduce the potential for splitting, install the TJC with a minimum 3/16″ edge distance on the chord members.

. Position the jack truss on the inside of the bend line with the end of the jack truss flush with the bend line.

. Bend the TJC to the desired position (one bend cycle only).

.No bevel cut required

. Attachment of TJC to the chord requires the designer to check connection geometry for placement on both carried and carrying chord members. See top chord member sizes table for suggested chord sizes.

. Supported jack member is a single 2X.