Project of the Month:

Project Of the Month:

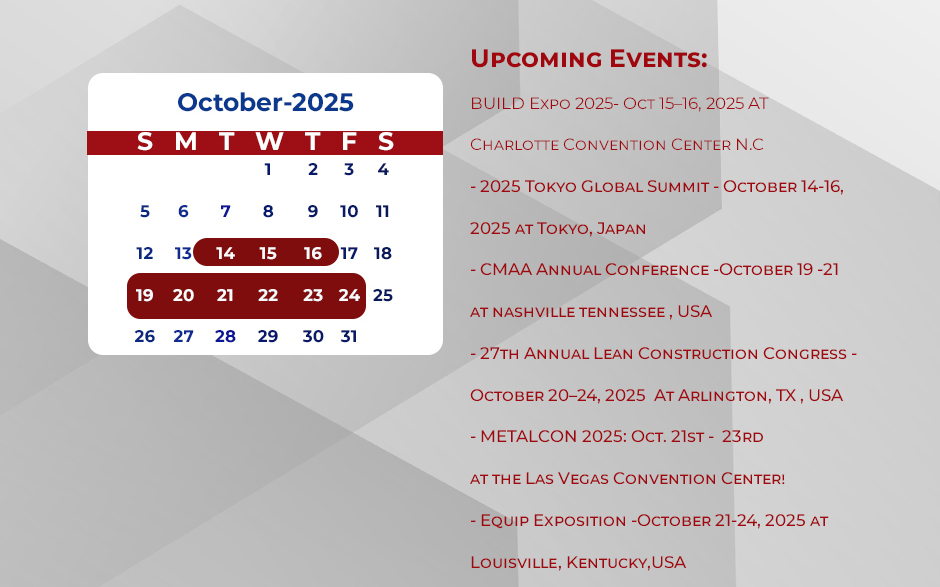

Project type: Residential Building

Area: 2707.9 sft

Storey: 1-storey

Roof: Multi-sloped roof

Scope of Work: Truss Engineering

3D Modelling

Detailing

CNC Production Files

Project Description:

This residential building project is of area 2,707.9 sq.ft in California,USA and features a single-storey layout with a multi-sloped roof, designed to combine aesthetic appeal with structural efficiency. The project scope included complete truss engineering, 3D modeling, detailed structural drawings, and CNC production files, ensuring seamless transition from design to fabrication. The trusses were engineered to optimize load distribution across the roof while maintaining architectural integrity.

A key feature of this project is the integrated in-built gutter system, thoughtfully incorporated within the truss layout to facilitate efficient water drainage while preserving the roof’s clean lines. Additionally, horizontal bracing was strategically placed at quarter points along the trusses, enhancing lateral stability and ensuring long-term durability of the structure. The project demonstrates a balance of functionality, precision engineering, and careful attention to detail, making it a robust and aesthetically appealing residential solution.

Software: Revit , MWF structsoft

Machine Used: FrameCAD

Industry Insights:

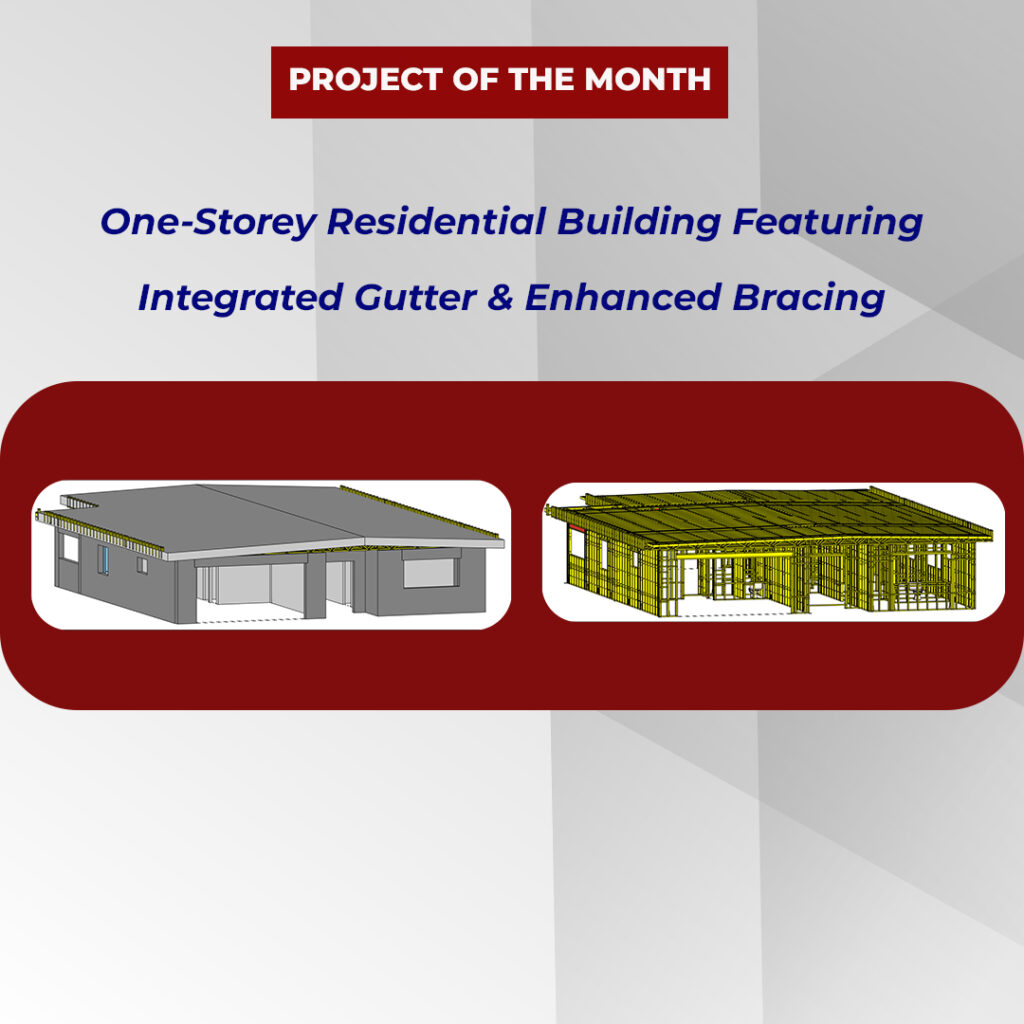

The Mercy Hall redevelopment at Loyola University in New Orleans, Louisiana, is a $75 million, seven-story student housing project that will provide 612 beds across 126 units. Spanning more than 210,000-square-feet, the structure combines post-tensioned concrete with prefabricated cold-formed steel (CFS) exterior wall panels to accelerate the schedule and improve efficiency. A key factor in the project’s success is the use of advanced roll-forming technology from Howick, a member of the Steel Framing Industry Association (SFIA). Howick’s cold-formed steel roll-forming tech cut on-site labor needs by 65% and accelerated the project schedule by 20% Read More

Technical Snippet

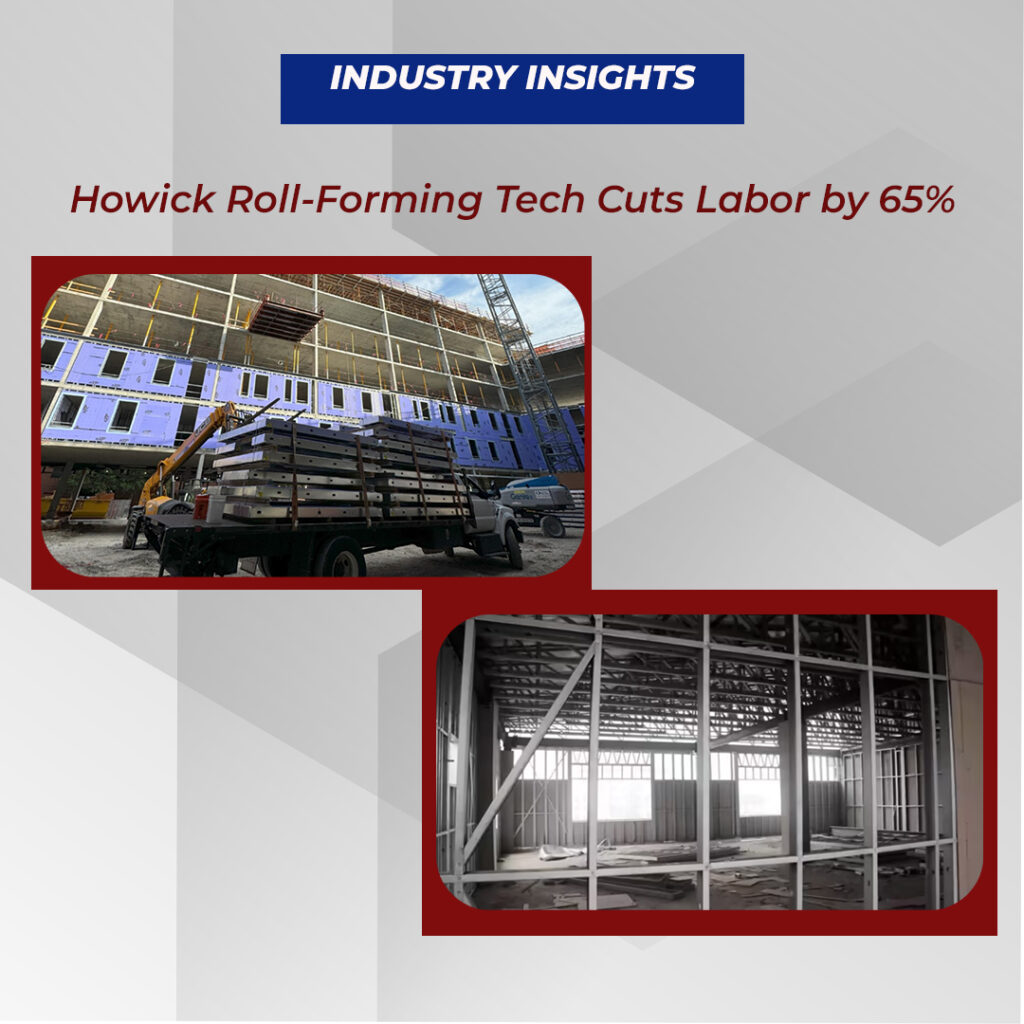

The S/HDU series of holdowns combines performance with ease of installation. The pre-deflected geometry virtually eliminates material stretch, resulting in low deflection under load. Installation using self-drilling screws into the studs reduces installation time and saves labor cost.These typical hold-downs are used for concrete to floor , floor to floor.