Evgeny Shishkin, Founder of Stroylider LLC, along with Mikhail, visited UBC to explore potential collaborations and gain insights into its innovative framing solutions

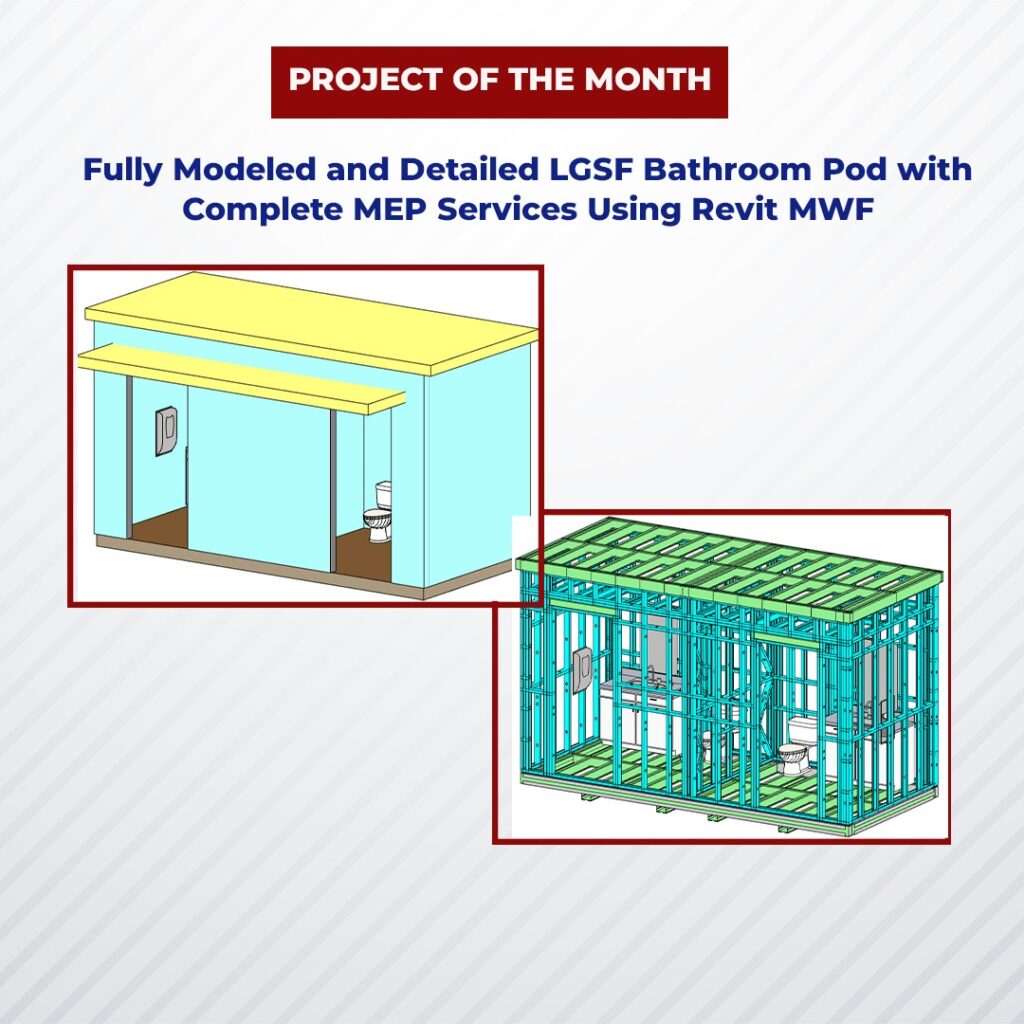

Project Of The Month

Project Type: Toilet Pod

Location: Nebraska,usa

Area:146 SFT

Roof-Flat roof

Material: LGSF building

Scope of Work: MODELLING, DETAILING, ENGINEERING, PERMIT SET, CNC PRODUCTION FILES

Project Description:

Duration: 8 hrs

Software: Modelling & Detailing – FRAMECAD Structure

Engineering-Strap

Machine Used: FRAMECAD

Industry Insigths

Total cold-formed steel (CFS) manufacturing volume in the United States increased 1.7% during Q1 2025 compared with the same quarter one year ago, Steel Framing Industry Association (SFIA) data show. read more

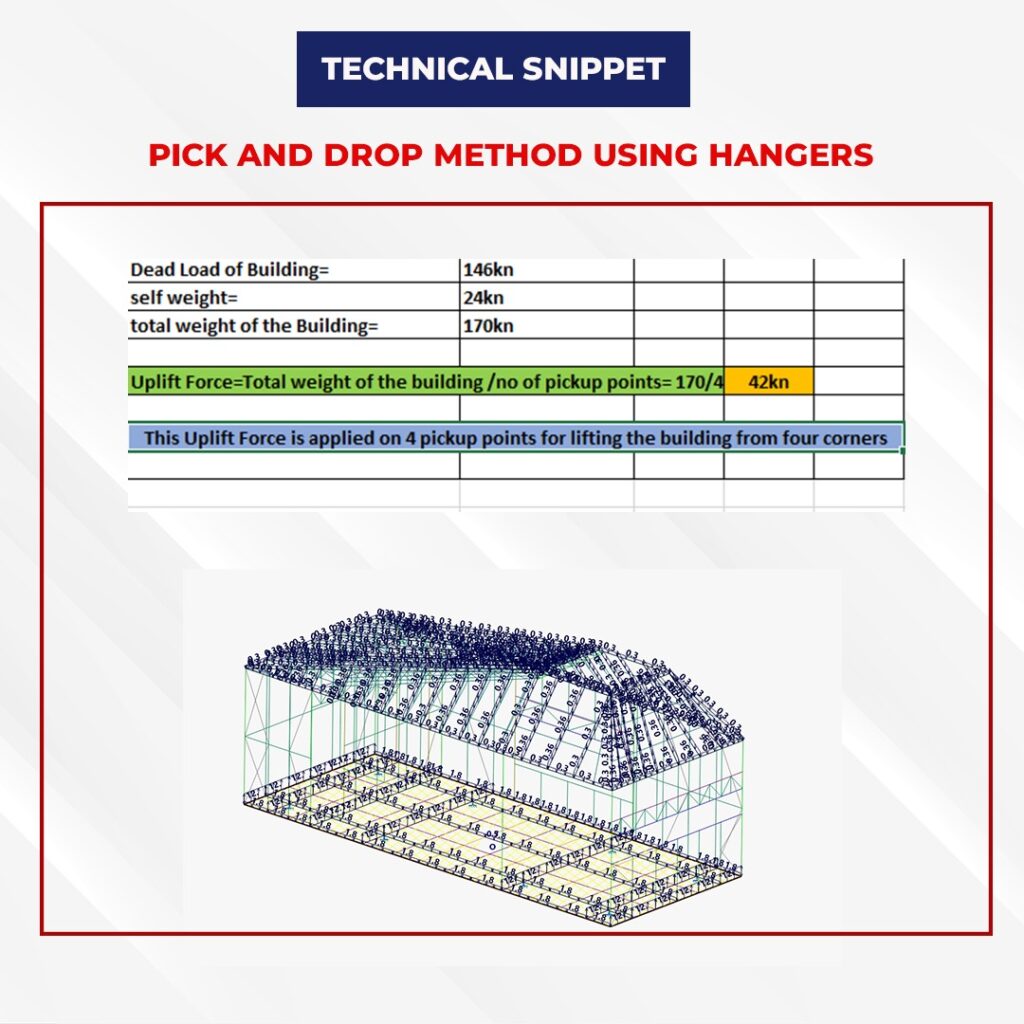

Technical Snippet

Pick and Drop Method Using Hangers in LGSF Construction

In LGSF projects, speed and precision during installation are critical. The Pick and Drop method using hangers is an efficient on-site strategy to handle and install prefabricated panels—especially for walls, trusses, and floor systems.

🔧 What Is It?

The Pick and Drop method refers to the lifting, positioning, and placement of pre-assembled LGSF panels using engineered lifting hangers (or lifting eyes) embedded or temporarily attached to the panel structure.

🛠️ How It Works:

1. Lifting Hangers Installation:

Before shipment or at site, lifting hangers (often bolted or welded) are installed at structurally safe points of the panel to ensure balance during lifting.

2. Rigging Setup:

Certified slings and spreader bars are connected to cranes or forklifts. Slings are hooked to the hangers to evenly distribute the weight of the panel.

3. Pick (Lifting):

The panel is carefully lifted off the staging area, maintaining level and orientation to avoid deformation.

4. Drop (Placement):

The panel is guided by crew members and dropped into place on anchor points or floor tracks, ensuring proper alignment with adjacent panels.

5. Detachment & Reuse:

Hangers are removed or left if they’re designed to be part of the structure. In many cases, they are reusable lifting accessories.

✅ Benefits:

• Faster panel installation, especially for large walls and roof trusses

• Reduced labor fatigue and manual handling injuries

• Minimized structural deformation during handling

• Improved site logistics—lift directly from truck to position

⚠️ Key Considerations:

• Use certified lifting hangers rated for the panel weight

• Ensure lifting points align with structural studs or headers

• Always perform a rigging and safety check before lifting

• Follow local OSHA or safety regulations during lifting operations