Company Event :

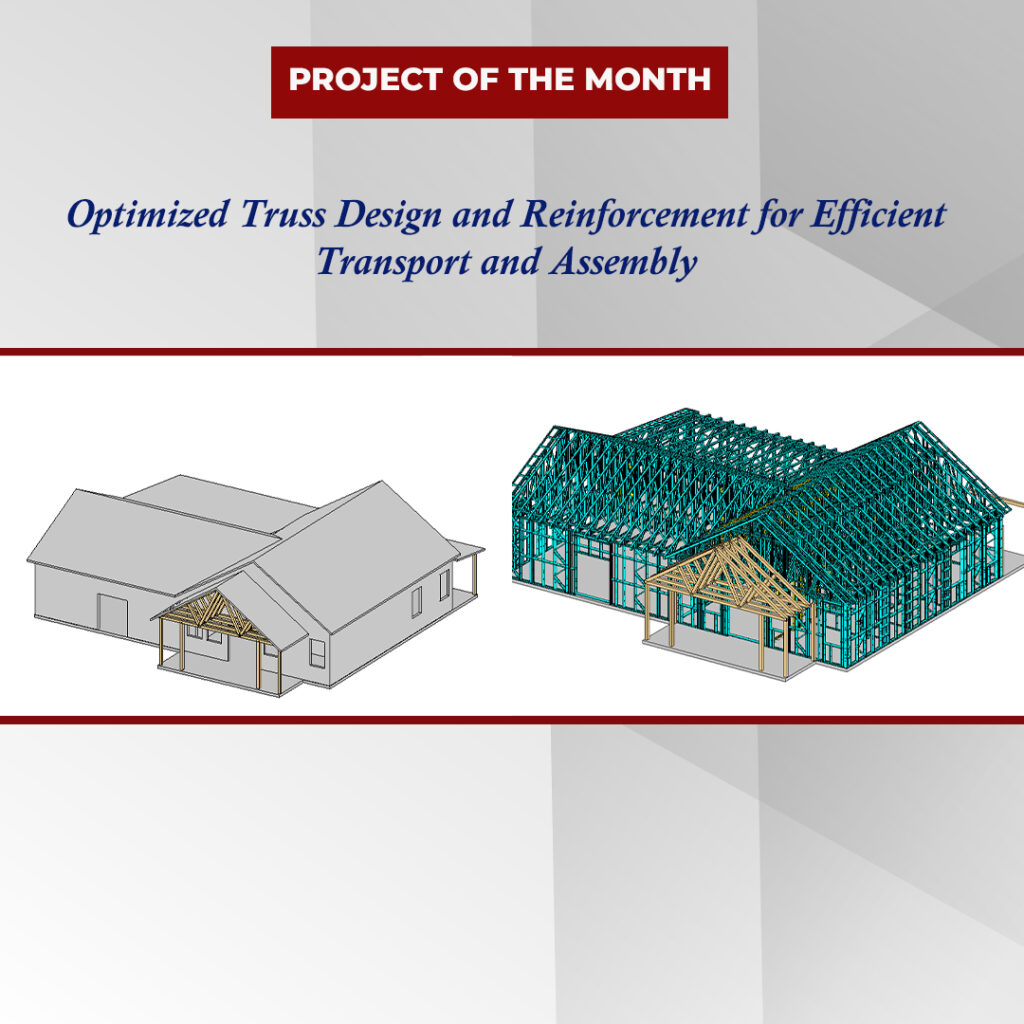

Project of the Month :

Project Type : Residential Building

Area : 3094 sft

Roof : Multi – sloped roof

Storey : 1- Storey

Scope of Work : Engineering

3D Modeling

Detailing

CNC Production files

Software Used : Revit Automation & Customization Training and Project Consultant,

MWF Structsoft

Machine Used : FRAMECAD

Project Description :This 3,094 sq. ft. single-storey residential building features a multi-sloped roof engineered for precision and efficiency. Using Revit MWF Structsoft and FrameCAD, UBC handled the complete scope — engineering, 3D modeling, detailing, and CNC production files. Due to the long span without intermediate supports, the roof truss system was reinforced to enhance stability. For ease of transportation, the truss was split into two halves, and a truss-to-truss connection was designed to ensure structural integrity after assembly. This project highlights UBC’s capability to deliver innovative, accurate, and constructible solutions through advanced design and prefabrication technologies.

Industry Insights :

There are growing insurance advantages of cold-formed steel (CFS). In some cases, those advantages are big enough to change a pro forma.

When a Midwest hotel developer received updated builder’s risk pricing on a new six-story project framed in CFS, they didn’t believe the number. Read More

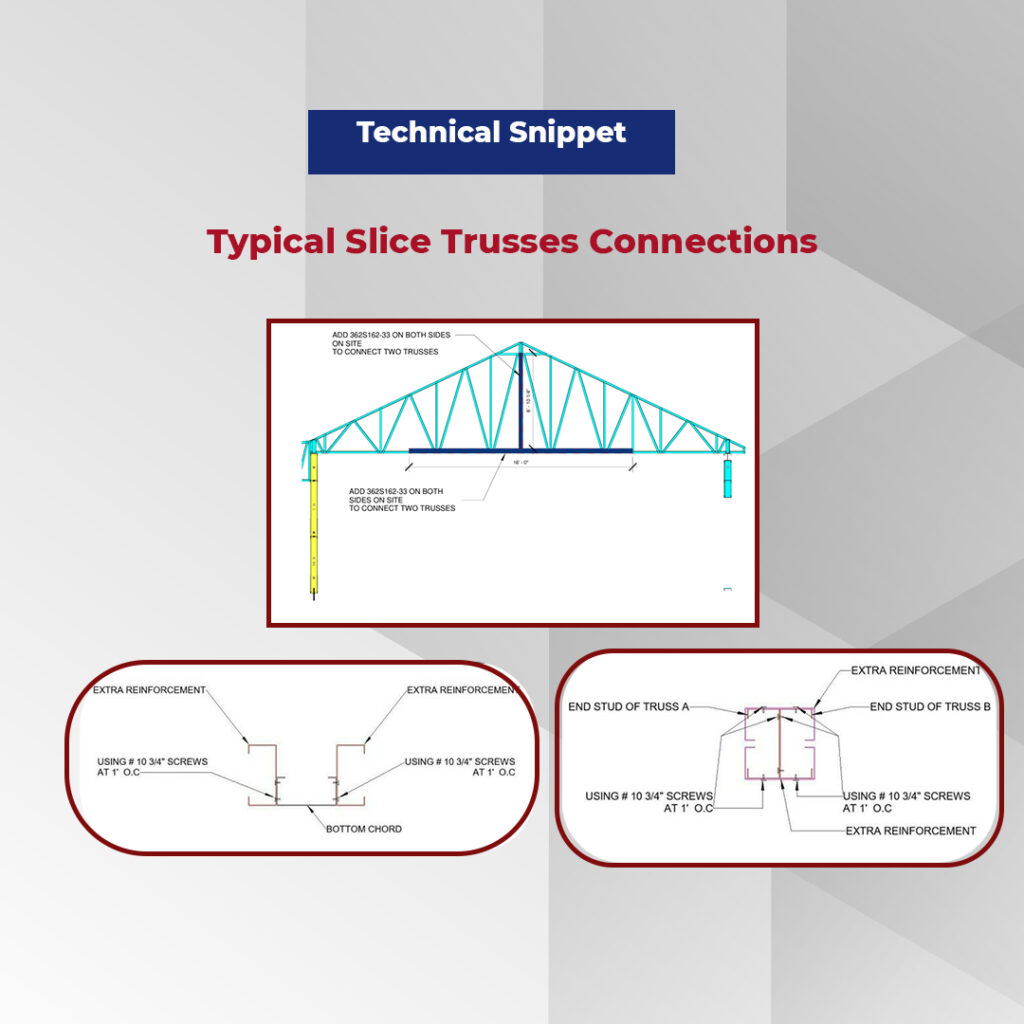

Technical Snippet :

Typical Truss Connection

For logistical purposes, the large truss was divided into two halves and for upon reassembing, additional reinforcement members are provided between the two trusses to ensure effective load transfer and bottom chord connection sections were added to restore integrity and to provide additional stability to the entire truss system.